CNC machining services forUSA

Buy durable, high-precision parts

CY's CNC machining services, in USA , makes quality components for your demand.

We are DongGuan ChengYang, a leading CNC machining service provider catering to the needs of clients in Arizona. Our company specializes in providing high-quality CNC machining services for various industries, including aerospace, automotive, medical, and more. With our state-of-the-art equipment and experienced team of engineers, we are able to deliver precision parts and components to meet the specific requirements of our Arizona-based customers.

Our CNC machining services for Arizona are known for their efficiency, accuracy, and reliability. Whether you need prototype development, small batch production, or mass production, we have the capabilities to handle projects of any size and complexity. We take pride in our commitment to delivering top-notch machining solutions that exceed our clients' expectations and help them achieve their business goals.

At DongGuan ChengYang, we understand the importance of providing exceptional customer service along with our CNC machining services for Arizona. Our team is dedicated to ensuring that every project is completed on time and within budget, while maintaining the highest standards of quality and precision. Trust us to be your reliable partner for all your CNC machining needs in Arizona.

CNC Machining services

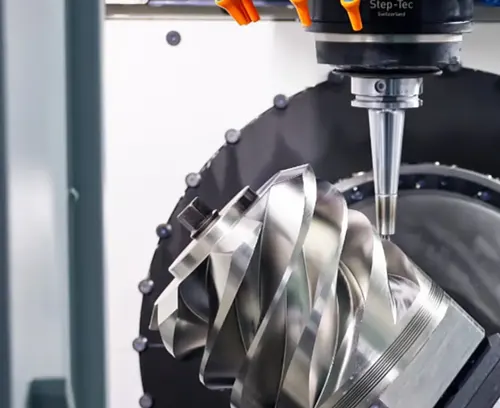

We are equipped with 3-axis, 4-axis, and 5-axis CNC milling machines, permits us to productively machining component ranging from elementary to sophisticated.

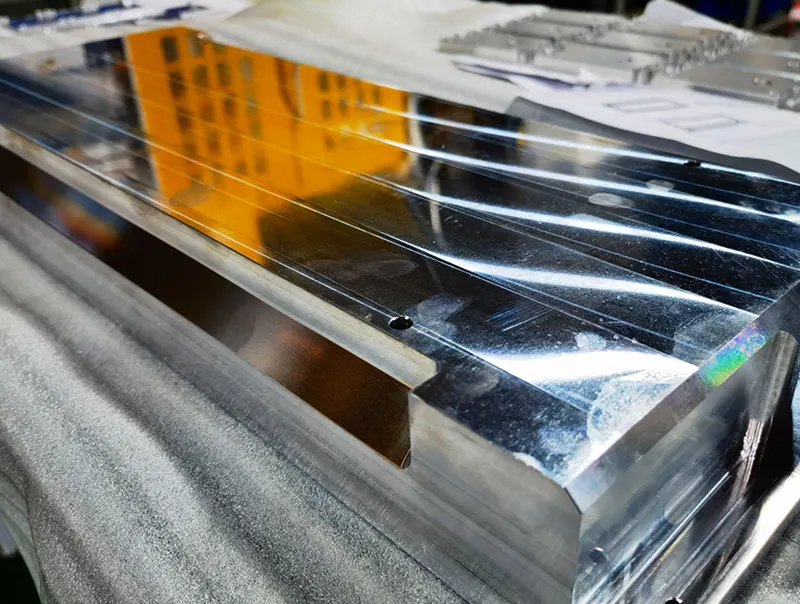

CNC Milling

Our shop features CNC milling capabilities, manufacturing precision parts with short lead times.

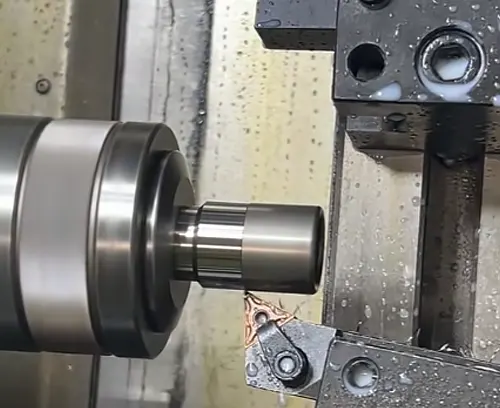

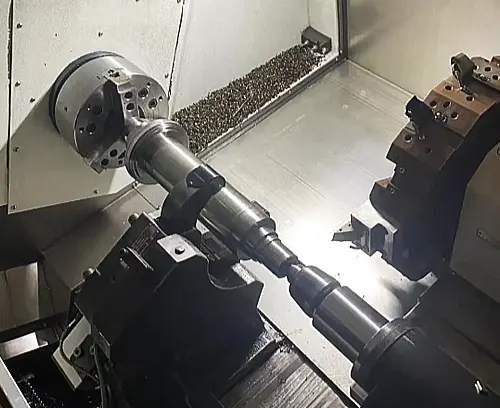

CNC Turnning

Our CNC lathes, turning centers, and mill-turn equipment enable us withhigh quality to construct a broad range of components for every consumer.

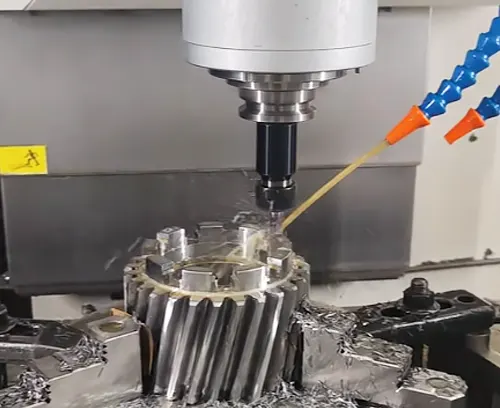

5 Axis CNC Milling

Equip with 5-axis machining solutions for complex and finely calibrated components. Featuring quick production, it's perfect for intricate designs.

Precision Machining

Deliver high-precision machining by integrating various processes to improve workflow, consistency, and reduce turnaround time, guaranteeing reliable, high-quality output.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

DFM reduces production barriers by fine-tuning designs before they reach the factory floor.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.We simplify sourcing with instant quotes and side-by-side comparisons of processing costs for 100+ metals.

Aluminum

Aluminum is a popular material used in CNC machining due to its lightweight nature, excellent machinability, and corrosion resistance. It is commonly used in a variety of industries, including aerospace, automotive, and electronics. Some common types of aluminum materials used in CNC machining include 6061 aluminum, known for its good strength and weldability; 7075 aluminum, valued for its high strength-to-weight ratio; and 2024 aluminum, which offers good machinability and fatigue resistance. Other types, such as 5052, 5083, and 6063 aluminum, are also frequently utilized for their specific properties and applications in CNC machining processes. Overall, aluminum is a versatile and reliable material that is ideal for producing precise and intricate parts through CNC machining.

Carbon Steel

Carbon steel is a popular material for CNC machining due to its strength, durability, and versatility. It is an alloy of iron and carbon, with a low carbon content making it easier to machine, while higher carbon content increases its hardness and strength. Some common types of carbon steel used in CNC machining include AISI 1018, a general purpose mild steel with good machinability; AISI 1045, a medium carbon steel ideal for parts requiring high strength and hardness; and AISI 1144, a free machining steel with added sulfur for improved machinability. These materials are widely used in various industries for producing a wide range of parts and components with precise specifications.

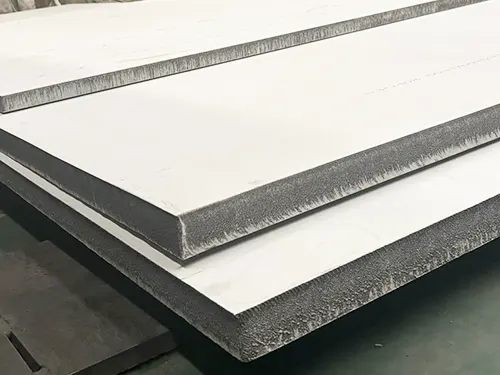

Stainless Steel

Stainless steel for CNC machining is a widely used material in the manufacturing industry due to its excellent mechanical and corrosion-resistant properties. It is known for its durability, high strength, and resistance to heat, making it a popular choice for a wide range of applications. Some common types of stainless steel materials used in CNC machining include 303 stainless steel, 304 stainless steel, 316 stainless steel, and 17-4 PH stainless steel. Each type has its own unique set of properties that make it suitable for different uses, ensuring that manufacturers have a variety of options to choose from depending on their specific requirements.

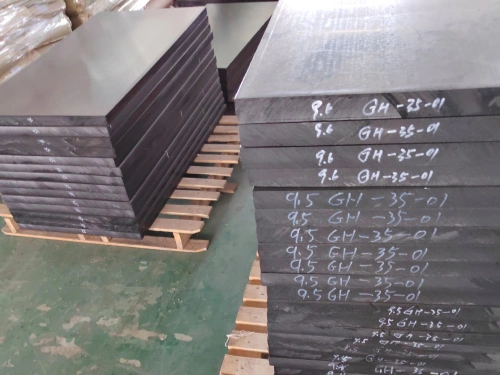

Tool Steel

Tool steel is a type of carbon and alloy steel that is specifically designed for use in the production of tools and molds. It is known for its enhanced durability, hardness, and resistance to abrasion, making it ideal for CNC machining applications. Common types of tool steel materials include D2 steel, which is highly wear-resistant and is often used for cutting tools; A2 steel, which has high toughness and good wear resistance; and M2 steel, known for its excellent heat resistance and ability to maintain sharp edges. Other popular tool steel materials used in CNC machining include O1 steel, S7 steel, and H13 steel, each offering unique properties to suit different machining needs.

Brass

Brass is commonly used in CNC machining due to its versatility, corrosion resistance, and excellent machinability. It is composed primarily of copper and zinc, which gives it a unique combination of properties that make it ideal for a variety of applications. Some common types of brass materials used in CNC machining include: C36000 (Free Cutting Brass), C38500 (Architectural Bronze), C46400 (Naval Brass), and C48500 (Naval Brass). Each type of brass has its own specific composition and characteristics, making them suitable for different machining projects. In CNC machining, brass is often utilized for creating precision parts, components, and prototypes in industries such as aerospace, automotive, and electronics.

Copper

In CNC machining, a cooper is a cutting tool used to remove excess material from a workpiece. Common types of materials used for coopers in CNC machining include high-speed steel, carbide, and ceramic. High-speed steel coopers are versatile and can be used for a wide range of materials, while carbide coopers are known for their hardness and durability, making them suitable for high-speed cutting operations. Ceramic coopers are ideal for high-temperature applications and provide excellent wear resistance. The choice of cooper material depends on the specific requirements of the machining operation, such as material hardness, cutting speed, and surface finish desired. Proper selection and maintenance of coopers are essential for achieving optimal machining results.

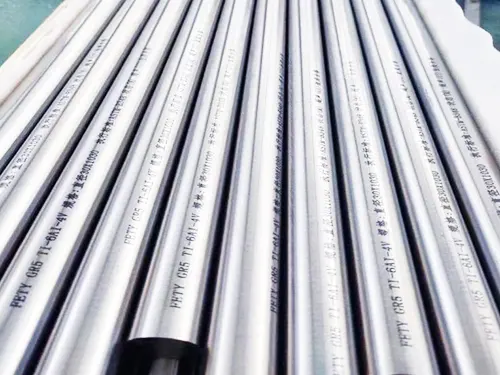

Titanium

Titanium is a popular material used in CNC machining due to its exceptional strength, corrosion resistance, and lightweight properties. This makes it ideal for applications where durability and precision are crucial. Common types of titanium materials used in CNC machining include Titanium Grade 2, Titanium Grade 5, and Titanium Grade 7. Titanium Grade 2 is the most widely used form of titanium and is known for its excellent weldability and formability. Titanium Grade 5, also known as Ti-6Al-4V, is a high-strength alloy with good heat resistance, making it suitable for aerospace and medical implants. Titanium Grade 7 is a corrosion-resistant alloy that offers great weldability and is often used in chemical processing applications.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic used in CNC machining. Its advantages include high strength, impact resistance, and good machinability, making it ideal for a wide range of applications. ABS is also known for its good dimensional stability and excellent surface finish. However, one disadvantage of ABS is its tendency to warp when exposed to high temperatures, which can complicate the machining process. Another downside is its susceptibility to chemical degradation over time. Despite these drawbacks, ABS remains a popular choice for CNC machining due to its overall ease of use and versatility. Additionally, ABS is relatively affordable compared to other engineering plastics, making it cost-effective for many manufacturing projects.

PMMA

PMMA, or polymethyl methacrylate, is a widely used material in CNC machining due to its excellent machinability and versatility. One of the main advantages of PMMA is its high transparency, which makes it ideal for applications that require optical clarity, such as prototype covers or lenses. PMMA is also known for its high impact resistance and weatherability, making it a durable choice for various outdoor and indoor applications. However, PMMA does have some disadvantages, including its tendency to scratch easily and its poor resistance to certain chemicals. Additionally, PMMA can be relatively expensive compared to other materials used in CNC machining. Despite its drawbacks, PMMA remains a popular choice for many CNC machining projects due to its overall performance and versatility.

PE

PE (Programmable Electronic) for CNC machining refers to the process of using software to input, modify, and control the operations of a CNC machine. One advantage of PE for CNC machining is the ability to easily program complex shapes and patterns with precision, saving time and reducing errors. Additionally, PE allows for easy editing and modification of programs, providing flexibility in production processes. However, a disadvantage of PE for CNC machining is the initial cost of investing in the software and training employees on how to use it effectively. Additionally, relying solely on PE for CNC machining may lead to a dependence on technology, potentially reducing manual machining skills among operators. Overall, PE for CNC machining offers numerous benefits in terms of efficiency and precision, but it is important to weigh these advantages against potential drawbacks.

Nylon

Nylon is a popular choice for CNC machining due to its versatility and durability. It is a thermoplastic material that is commonly used for producing various components and parts in CNC machining processes. One of the main advantages of using Nylon for CNC machining is its excellent strength-to-weight ratio, making it ideal for applications where both strength and lightweight characteristics are important. Additionally, Nylon has good chemical resistance, low friction properties, and can be easily machined to create intricate shapes and designs. However, Nylon does have some disadvantages as well. It is more susceptible to moisture absorption than some other materials, which can affect its mechanical properties. Additionally, Nylon can be prone to warping or shrinking if not properly handled during the machining process.

PEEK

PEEK, or polyetheretherketone, is a high-performance thermoplastic material often used in CNC machining. It is known for its excellent mechanical properties, chemical resistance, and temperature resistance, making it ideal for applications in industries such as aerospace, medical, and automotive. PEEK also offers good dimensional stability and low friction coefficient, resulting in high precision and smooth surface finishes during CNC machining. However, the main disadvantage of PEEK is its high cost compared to other materials, which can make it less economical for some projects. Additionally, PEEK has poor thermal conductivity, which can lead to challenges in cooling during machining processes. Overall, PEEK is a versatile material with unique advantages and disadvantages that should be carefully considered when selecting materials for CNC machining projects.

PC

A PC for CNC machining refers to a computer system that is specifically designed to control the operations of a CNC (Computer Numerical Control) machine. The advantage of using a PC for CNC machining is the flexibility it provides in terms of programming and controlling the machining process. With a PC, operators can easily create and modify machining programs, resulting in faster setup times and increased productivity. Additionally, PCs offer advanced simulation and visualization tools that help identify and correct potential issues before they occur, reducing the risk of errors and material waste. However, a disadvantage of using a PC for CNC machining is the initial investment required for the hardware and software. Additionally, PCs may be susceptible to cybersecurity threats, requiring extra precautions to safeguard the machining process from potential interruptions or data breaches.

PP

PP stands for Polypropylene, a thermoplastic that is commonly used in CNC machining processes. One of the main advantages of using PP for CNC machining is its low cost compared to other materials, making it an economical choice for prototyping and low-volume production. PP is also known for its excellent chemical resistance, making it ideal for parts that will be in contact with various substances. However, PP has some disadvantages as well. It has a lower tensile strength and stiffness compared to other materials, which can limit its applications for parts that require high mechanical properties. PP also has a lower melting point, which can make it susceptible to deformation at high temperatures. Despite these limitations, PP remains a popular material choice for CNC machining due to its affordability and versatility.

PET

PET (Polyethylene terephthalate) is a commonly used material in CNC machining due to its excellent machinability and versatility. It is a thermoplastic polymer that is ideal for producing prototypes, parts, and components with intricate geometries. PET offers several advantages such as high strength, good chemical resistance, and low moisture absorption. It also has excellent dimensional stability, making it suitable for precision machining applications. However, PET does have some disadvantages, including poor heat resistance and limited resistance to certain solvents. It is important to consider these limitations when selecting materials for CNC machining projects. Despite its drawbacks, PET remains a popular choice for many applications due to its cost-effectiveness, ease of machining, and overall performance characteristics.

POM

POM, or Programmed Operator Machining, is a method of computer numerical control (CNC) machining that allows operators to manually control the movement of the machine through the use of software. One advantage of POM for CNC machining is that it allows operators to have more control over the machining process, resulting in a more customized and precise finished product. Additionally, POM can be more cost-effective than fully automated CNC machining, as it requires less complex programming and can be adapted quickly to accommodate changes in production requirements. However, a disadvantage of POM is that it relies heavily on operator skill and attention, which can lead to errors or inconsistencies in the machining process if not carefully monitored. Overall, POM for CNC machining offers a balance between automation and manual control that can be beneficial for certain applications.

PVC

PVC, or polyvinyl chloride, is a widely used material in CNC machining due to its excellent machinability and cost-effectiveness. Its advantages include high strength and durability, resistance to chemicals and weathering, and ease of fabrication. PVC also has good electrical insulation properties, making it suitable for a wide range of applications. However, one disadvantage of PVC in CNC machining is that it can release toxic fumes when heated, posing a health risk to operators. Additionally, PVC is prone to warping and shrinking during the machining process, requiring careful consideration of processing parameters. Despite these drawbacks, PVC remains a popular choice for CNC machining projects where its benefits outweigh the potential challenges.

Surface Finishes

We take pride in offering expert surface treatment services delivered by seasoned specialists.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is a fundamental oral hygiene practice that involves cleaning the teeth and gums using a toothbrush and toothpaste. It removes food particles, plaque, and bacteria, preventing tooth decay, gum disease, and bad breath. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sand blasting is a process used to clean, smooth, or shape a surface by propelling sand or other abrasive materials at high speeds. It is commonly used in industrial applications to remove old layers of paint or rust. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves performing a series of acrobatic movements, such as flips, twists, and somersaults. It requires strength, flexibility, coordination, and balance to execute these skills effectively. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is the process of refining a surface to improve its appearance, remove imperfections, and enhance its overall quality. It typically involves smoothing out rough edges, removing scratches, and restoring a smooth, shiny finish. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that creates a protective oxide layer on metals such as aluminum. This layer enhances corrosion resistance, durability, and aesthetic appeal. Anodizing can be colored and dyed for various applications. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a form of art in which colors are applied to a surface using various techniques. It allows artists to express emotions, convey messages, and capture the beauty of the world. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a conversion coating used to blacken ferrous metals, such as steel or iron, to enhance their resistance to corrosion and wear. This chemical process forms a dark, protective layer on the metal surface. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process where a metal object is coated with a thin layer of another metal using electricity. This technique is commonly used to improve the appearance, corrosion resistance, and durability of various items. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process used to apply a free-flowing, electrostatically charged powder material onto a surface. The powder is then heated to fuse into a smooth, durable coating. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine, also known by its chemical name chromate conversion coating, is a type of chemical treatment applied to metals like aluminum. It helps improve corrosion resistance and paint adhesion, making it a common pre-treatment for aerospace and defense applications. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a chemical process used to protect metal surfaces from corrosion. It involves the deposit of a thin layer of a protective material onto the metal to create a barrier against environmental factors that could cause deterioration. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process where metal ions in a solution are deposited onto a surface without the need for an external power source. It provides uniform and corrosion-resistant coatings for various industries. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Arizona, USA

We’re specialists in surface treatment, backed by a team of experienced professionals.

FAQ

Here, some of the most common questions about CNC machining services for Arizona, USA. ” free to contact us if you have any question.”

Introduction

If you’re looking for reliable CNC machining services in Arizona, USA, you probably have a lot of questions. To help you make an informed decision, we’ve compiled a list of 10 pairs of frequently asked questions about CNC machining services in Arizona, along with their answers.

Q: What is CNC machining?

A: CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory machinery and tools. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

Q: What industries benefit from CNC machining services in Arizona?

A: CNC machining services are utilized in a wide range of industries in Arizona, including aerospace, automotive, medical, and electronics. These industries benefit from the precision, efficiency, and versatility of CNC machining technology.

Q: How can I find a reliable CNC machining service provider in Arizona?

A: When looking for a CNC machining service provider in Arizona, it’s important to consider factors such as experience, reputation, capabilities, and customer reviews. Researching online, asking for recommendations, and requesting quotes can also help you find a reliable provider.

Conclusion

By understanding the ins and outs of CNC machining services in Arizona, you can make the best decision for your business needs. Whether you’re looking to prototype a new product or need high-volume production, finding the right CNC machining service provider is key to achieving your manufacturing goals.