CNC machining services forUSA

Order top-quality mechanical components

CY's CNC machining services, in USA , makes quality components for your requiements.

DongGuan ChengYang is a leading provider of CNC machining services for Iowa, offering high-quality precision machining solutions to meet the needs of various industries. With a team of skilled technicians and state-of-the-art machinery, we are dedicated to delivering superior results that exceed our clients' expectations.

Our commitment to excellence drives us to continuously improve our processes and technology to ensure optimal efficiency and accuracy in every project we undertake. Whether you require prototyping, production runs, or custom machined parts, we have the capabilities to accommodate your unique requirements with precision and attention to detail.

At DongGuan ChengYang, we take pride in our ability to deliver reliable and cost-effective CNC machining services for Iowa businesses. Contact us today to learn more about how we can assist you with your machining needs and provide you with the quality service you deserve.

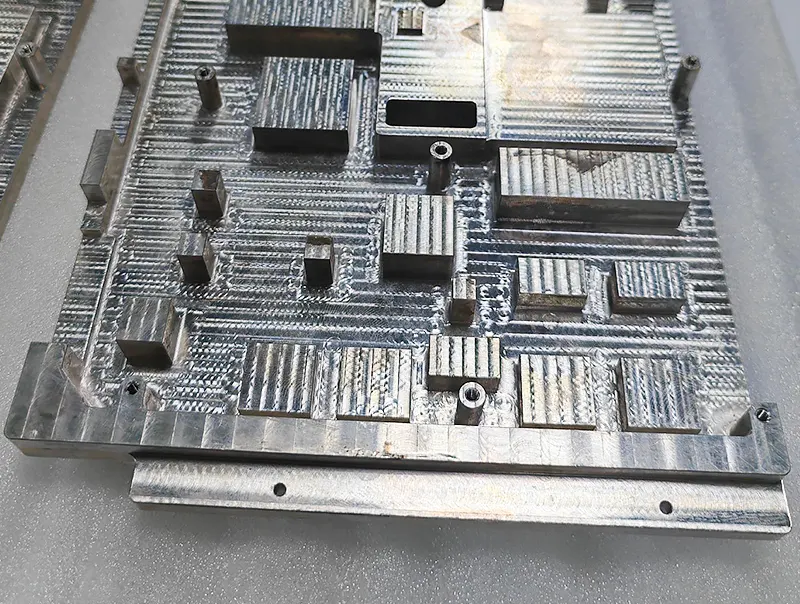

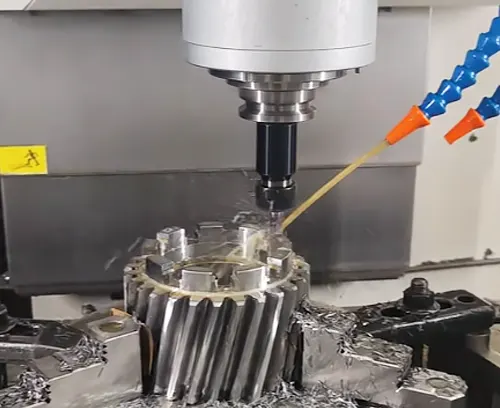

CNC Machining services

We are equipped with 3-axis, 4-axis, and 5-axis CNC milling machines, provides us to proficiently processing part ranging from elementary to sophisticated.

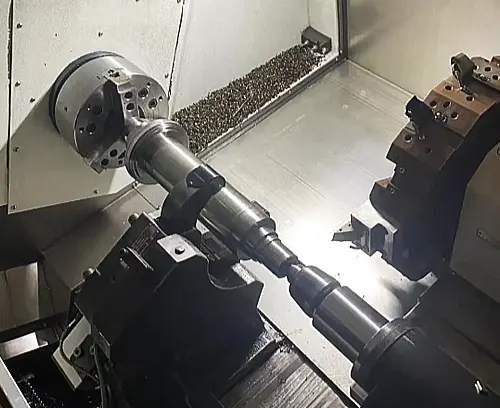

CNC Milling

Utilizing both CNC technologies for versatile production, delivering dependable parts quickly for our customers.

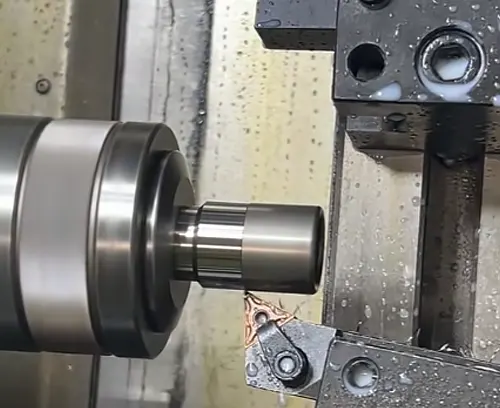

CNC Turnning

CY's CNC lathes, turning centers, and mill-turn equipment enable us withpresicion to fabricate a broad range of parts for every end user.

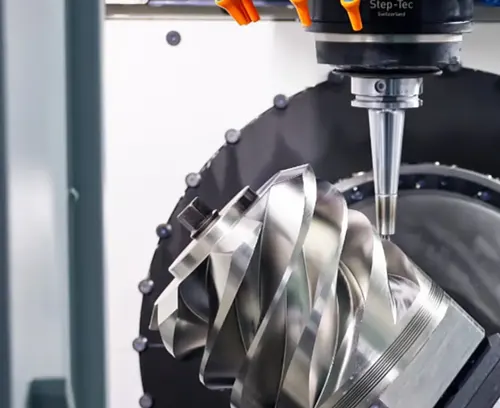

5 Axis CNC Milling

Equip with 5-axis machining solutions for complicated and exacting parts. Featuring faster processing, it's perfect for complex designs.

Precision Machining

Provide expert machining solutions by aligning different manufacturing stages to maximize efficiency, precision, and minimize delays, assuring efficient, top-level manufacturing performance.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

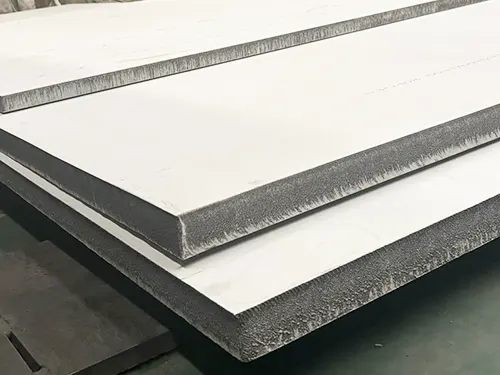

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

DFM helps manufacturers cut costs and prevent issues by adjusting the design during the early stages of development.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

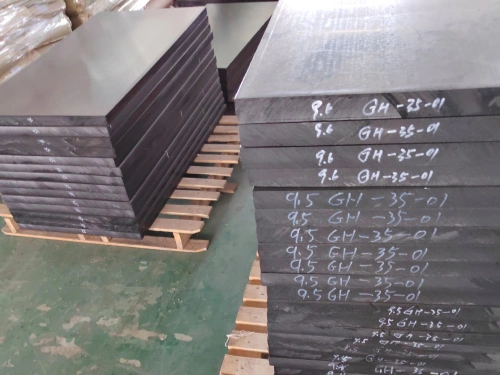

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.Choose from 100+ metals, get instant pricing, and compare processing costs in one step.

Aluminum

Aluminum is a popular choice for CNC machining due to its lightweight yet sturdy properties, making it ideal for a wide range of applications. It is a versatile material that is easily machined and can be anodized for added protection and aesthetics. Some common types of aluminum materials used in CNC machining include 6061 aluminum, which offers excellent strength and weldability, 7075 aluminum known for its high strength-to-weight ratio, and 2024 aluminum, which is often used in aerospace applications due to its high fatigue resistance. Other common types of aluminum alloys used in CNC machining include 5052, 5083, and 6063, each with its own unique set of properties suited for different machining needs.

Carbon Steel

Carbon steel is a popular material choice for CNC machining due to its cost-effectiveness, durability, and machinability. It is an alloy comprised of iron and carbon, with varying levels of carbon content affecting the material’s strength, hardness, and flexibility. Some common types of carbon steel used in CNC machining include low carbon steel, medium carbon steel, and high carbon steel. Low carbon steel, also known as mild steel, is easy to shape and weld, making it suitable for general machining tasks. Medium carbon steel is stronger and more wear-resistant, often used for shafts and gears. High carbon steel offers excellent hardness and edge retention, making it ideal for cutting tools and blades. Each type of carbon steel has unique properties that can be tailored to specific machining requirements.

Stainless Steel

Stainless steel is a type of metal alloy that is commonly used in CNC machining due to its high strength, corrosion resistance, and durability. It is composed of iron, carbon, and at least 10.5% chromium, which forms a passive layer of oxide that prevents rust and corrosion. Some common types of stainless steel materials used in CNC machining include 304 stainless steel, which is versatile and commonly used in various industries, 316 stainless steel, which is known for its excellent corrosion resistance, and 17-4 stainless steel, which offers a combination of high strength and good corrosion resistance. These materials are widely used in CNC machining for producing high-quality parts and components for various applications.

Tool Steel

Tool steel is a type of steel specifically designed for use in cutting, shaping, and forming materials in CNC machining processes. It is known for its high hardness, wear resistance, and ability to retain its shape even at high temperatures. Some common types of tool steel used in CNC machining include D2, A2, O1, M2, and S7. D2 tool steel is known for its high resistance to wear and abrasion, making it ideal for cutting and forming tools. A2 tool steel is valued for its toughness and ability to retain sharp cutting edges. O1 tool steel is popular for its ease of machining and good wear resistance. M2 tool steel is known for its excellent heat resistance and hardness. S7 tool steel is prized for its shock resistance and high impact strength.

Brass

Brass is a popular material used in CNC machining due to its excellent machinability and corrosion resistance. It is an alloy of copper and zinc, with varying proportions of other elements such as lead or tin added to achieve specific properties. Common types of brass used in CNC machining include C36000, also known as free-cutting brass, which is highly machinable and ideal for intricate parts. Another common type is C46400, or naval brass, which contains a higher amount of zinc and tin, making it more resistant to corrosion in seawater. Additionally, C26000, or cartridge brass, is often used for electrical components due to its good conductivity. These variations in composition allow for a wide range of brass materials to be used in CNC machining for various applications.

Copper

A cooper for CNC machining is a type of cutting tool used to remove material from a workpiece to create a desired shape or form. Common materials used for coopers include high-speed steel, carbide, and ceramic. High-speed steel coopers are versatile and can be used on a wide range of materials. Carbide coopers are known for their durability and ability to withstand high temperatures, making them suitable for machining hard materials such as steel and titanium. Ceramic coopers are valued for their resistance to wear and heat, making them ideal for high-speed machining operations. Each type of material offers unique properties that can affect the efficiency and quality of the machining process.

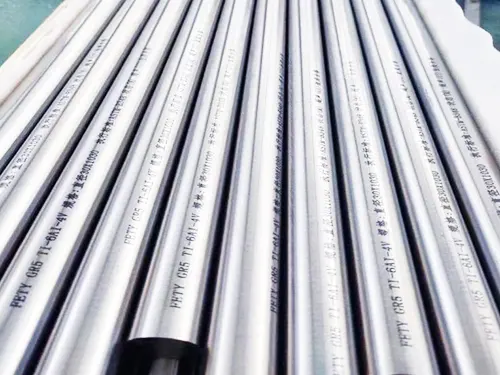

Titanium

Titanium is a popular material used in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It is often chosen for aerospace, medical, and automotive applications. Common types of titanium used in CNC machining include Grade 5 titanium (also known as Ti-6Al-4V) which is the most widely used titanium alloy, Grade 2 titanium which is commercially pure and offers good weldability, and Grade 1 titanium which is the softest and most ductile form of titanium. Other common materials used in CNC machining include aluminum alloys such as 6061 and 7075, stainless steel grades like 304 and 316, and engineering plastics such as ABS and PEEK.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic material used in CNC machining. Its advantages include high impact resistance, good strength-to-weight ratio, and the ability to be easily machined and finished. ABS is also cost-effective, making it a popular choice for rapid prototyping and low-volume production. However, ABS is prone to warping and shrinking during the cooling process, which can affect the dimensional accuracy of the final part. Additionally, ABS has relatively poor chemical resistance and is not suitable for applications where high temperatures are involved. Despite its disadvantages, ABS remains a versatile and widely used material in the CNC machining industry due to its favorable mechanical properties and ease of processing.

PMMA

PMMA, or polymethyl methacrylate, is a common material used in CNC machining due to its versatility and ease of use. Its advantages include high transparency, making it ideal for applications requiring a clear finish. PMMA is also lightweight and durable, making it suitable for a wide range of products. However, the material can be brittle and prone to cracking under stress, which is a significant disadvantage. Additionally, PMMA can be more challenging to machine than other materials, requiring careful consideration of cutting speeds and tooling. Despite these drawbacks, PMMA remains a popular choice for CNC machining due to its aesthetic appeal and cost-effectiveness.

PE

PE, or precision engineering, in CNC machining refers to the process of achieving high levels of accuracy and precision in the manufacturing of parts. Its advantage lies in the ability to produce complex components with tight tolerances, ensuring a high level of consistency and quality in the final product. This results in reduced scrap rates and enhanced reliability of the parts. However, the downside of PE for CNC machining is that it typically requires specialized equipment and skilled operators, leading to higher production costs. Additionally, the process can be time-consuming, especially for intricate designs, which may impact overall efficiency. Despite these drawbacks, the benefits of precision engineering in CNC machining make it a valuable tool for industries seeking top-quality, reliable components.

Nylon

Nylon is a synthetic polymer that is commonly used in CNC machining due to its excellent mechanical properties. It is known for its high strength, durability, and resistance to wear and tear. Nylon is also lightweight and has low friction, making it an ideal material for manufacturing a wide range of products. However, one disadvantage of using nylon in CNC machining is its tendency to absorb moisture, which can affect its dimensional stability and lead to inaccuracies in the final product. Additionally, nylon can be prone to warping and distortion under high temperatures, so special care must be taken during the machining process to prevent these issues.

PEEK

PEEK, which stands for polyetheretherketone, is a high-performance engineering thermoplastic that is frequently used in CNC machining. Its advantage lies in its exceptional mechanical properties, including high heat resistance, chemical resistance, and excellent optical clarity. PEEK is also biocompatible, making it a popular choice in medical applications. Additionally, PEEK is known for its ability to maintain its properties in harsh environments, such as exposure to high temperatures and corrosive chemicals. On the downside, PEEK is a relatively expensive material compared to other thermoplastics, which can drive up production costs. Furthermore, PEEK can be challenging to machine due to its high melting point and low thermal conductivity. Despite its drawbacks, the unique properties of PEEK make it a valuable material for CNC machining in various industries.

PC

A PC for CNC machining, or Computer Numerical Control machining, is a computer system used to control and manage the operations of CNC machines. The main advantage of using a PC for CNC machining is the high level of precision and accuracy it provides. This results in the production of complex and intricate parts that may be difficult to machine manually. Additionally, utilizing a PC allows for faster production times and increased efficiency in the manufacturing process. However, a disadvantage of using a PC for CNC machining is the initial cost of purchasing and setting up the system. Additionally, there may be a learning curve for operators who are not familiar with computer programming. Despite these challenges, the benefits of using a PC for CNC machining often outweigh the drawbacks in terms of precision, efficiency, and quality of production.

PP

PP, or Polypropylene, is a commonly used material in CNC machining due to its versatility and low cost. One major advantage of using PP for CNC machining is its excellent chemical resistance, making it ideal for applications where contact with various chemicals is expected. Additionally, PP is known for its high tensile strength and stiffness, making it a reliable choice for producing durable parts. However, one disadvantage of PP is its poor UV resistance, which can cause the material to degrade when exposed to sunlight for extended periods of time. Additionally, PP can be challenging to machine due to its low thermal conductivity, which can result in heat build-up during the machining process. Despite these drawbacks, PP remains a popular choice for CNC machining due to its overall advantageous properties.

PET

PET stands for Polyethylene Terephthalate, a type of plastic material commonly used in CNC machining processes. Its main advantage is its excellent dimensional stability, making it ideal for parts that require tight tolerances. PET is also resistant to chemicals and moisture, making it suitable for a wide range of applications. However, PET can be difficult to machine due to its tendency to melt easily and create burrs on the edges of the workpiece. Additionally, PET can be more expensive than other materials commonly used in CNC machining, which may be a disadvantage for cost-sensitive projects. Despite its drawbacks, PET remains a popular choice for CNC machining due to its versatility and durability.

POM

POM, or Precision Optical Manufacturing, is a cutting-edge technology used in CNC machining that allows for incredibly precise and accurate results. The advantage of POM in CNC machining is that it can achieve tight tolerances and smooth surface finishes that traditional machining methods may struggle to achieve. This leads to high-quality, flawless parts that meet the most demanding specifications. However, one disadvantage of POM is that it can be more costly due to the specialized equipment and expertise required. Additionally, the process can be more time-consuming than traditional machining methods, which may not be suitable for projects with tight deadlines. Overall, POM in CNC machining offers unparalleled precision but comes with its own set of challenges.

PVC

PVC, or polyvinyl chloride, is a widely used material in CNC machining due to its affordability, machinability, and chemical resistance. One of the main advantages of using PVC for CNC machining is its low cost compared to other engineering plastics, making it an ideal choice for prototyping or manufacturing parts in large quantities. PVC is also easy to machine and fabricate, allowing for intricate designs and complex geometries to be achieved with high precision. However, one disadvantage of using PVC for CNC machining is its tendency to produce harmful fumes when heated, which can pose health risks if proper ventilation is not in place. Additionally, PVC has lower mechanical properties compared to other engineering plastics, which may limit its applications in certain industries requiring high strength or durability.

Surface Finishes

We specialize in enhancing product surfaces through professional treatment services.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is the act of cleaning the teeth using a toothbrush and toothpaste. It helps to remove plaque, food particles, and bacteria from the teeth and gums, promoting good oral hygiene and preventing dental issues. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting is a method of propelling fine bits of material at high speeds to clean or etch a surface. Commonly used on metal, glass, and stone, sandblasting can remove rust, paint, or other coatings effectively. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves performing acrobatic movements, such as flips, twists, and somersaults. It requires strength, flexibility, and coordination to execute these movements safely and effectively. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a process of smoothing and shining a surface through friction or abrasion. It is commonly used in various industries such as automotive, furniture, and jewelry to improve the appearance and durability of the object. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that enhances the corrosion resistance and durability of metal surfaces. By forming a protective oxide layer through the application of an electric current, anodizing also provides aesthetic benefits and improves adhesion for further finishing processes. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form where colors are applied to a surface using various techniques. It serves as a medium of self-expression and can evoke emotions, tell stories, and capture moments in time. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a chemical process used to create a blackened surface on ferrous metals. This finish provides corrosion resistance and a sleek appearance. It is commonly used in industrial applications for its durability. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process of coating an object with a thin layer of metal through the use of an electric current. This technique is commonly used for decorative or protective purposes in industries. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto a metal surface. The parts are then cured under heat, resulting in a tough, uniform, and long-lasting coating. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine is a chemical conversion coating used to protect aluminum surfaces from corrosion and improve paint adhesion. It creates a thin, protective layer that enhances the durability and longevity of the metal. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a chemical process used to remove surface contaminants from metals, such as stainless steel, to prevent corrosion. It creates a protective oxide layer, enhancing the metal's resistance to rust and other forms of corrosion. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process used to deposit a metal coating onto a substrate without the need for an external electrical current. It relies on chemical reactions to form a uniform and corrosion-resistant layer. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Iowa, USA

We bring years of hands-on experience in treating product surfaces to perfection.

FAQ

Here, some of the most common questions about CNC machining services for Iowa, USA. ” free to contact us if you have any question.”

Introduction

When it comes to CNC machining services in Iowa, USA, there are many questions that individuals and businesses may have. Whether you are looking to learn more about the process, capabilities, or benefits of CNC machining, this article will provide answers to some of the most commonly asked questions.

Q: What is CNC machining?

A: CNC machining, or computer numerical control machining, is a manufacturing process that utilizes pre-programmed computer software to control the movement of machinery and tools. This technology is used to create precise and complex parts from a variety of materials.

Q: What are the advantages of using CNC machining services?

A: Some of the benefits of CNC machining services include increased efficiency, accuracy, repeatability, and the ability to produce high-quality parts with tight tolerances.

Q: What materials can be used in CNC machining?

A: CNC machining can work with a wide range of materials, including metals such as aluminum, steel, and titanium, as well as plastics, wood, and composites.

Q: How long does it take to complete a CNC machining project?

A: The timeframe for completing a CNC machining project can vary depending on the complexity of the parts, the materials used, and the quantity being produced. Generally, projects can be completed in a matter of days or weeks.

Q: What industries can benefit from CNC machining services?

A: Industries such as aerospace, automotive, medical, and electronics can benefit greatly from CNC machining services due to the precision and versatility of the technology.

Q: Can custom parts be created with CNC machining?

A: Yes, CNC machining allows for the creation of custom parts based on specific design requirements. This flexibility makes it an ideal choice for prototyping and low-volume production.

Q: How does CNC machining compare to traditional machining methods?

A: CNC machining offers advantages over traditional machining methods such as increased accuracy, efficiency, and the ability to produce complex geometries that would be challenging with manual methods.

Q: What is the cost of CNC machining services?

A: The cost of CNC machining services can vary depending on factors such as the complexity of the parts, the materials used, and the quantity being produced. It is best to request a quote from a CNC machining provider for accurate pricing information.

Q: Are CNC machining services available in Iowa, USA?

A: Yes, there are CNC machining services available in Iowa that can cater to the needs of local businesses and individuals. By partnering with a reputable CNC machining provider, clients can access high-quality manufacturing solutions.

Q: How can I find a reliable CNC machining service provider in Iowa?

A: To find a reliable CNC machining service provider in Iowa, it is recommended to research and compare different companies based on factors such as experience, capabilities, quality of work, and customer reviews. Referrals from trusted sources can also be helpful in identifying a reputable provider.

Conclusion

As CNC machining continues to revolutionize the manufacturing industry, having a clear understanding of the process and its benefits is essential for those looking to leverage this technology. By addressing common questions and concerns about CNC machining services in Iowa, this article aims to provide valuable insights for individuals and businesses seeking reliable manufacturing solutions.