CNC machining services forUSA

Submit your order for premium custom parts

Our CNC machining services, in USA , makes precision components for your needs.

DongGuan ChengYang is a leading CNC machining service provider catering to the needs of Louisiana. With a team of skilled professionals and state-of-the-art technology, we strive to deliver high-quality precision machining services to our clients in Louisiana.

Our CNC machining services are tailored to meet the specific requirements of businesses in Louisiana, offering a wide range of machining solutions to suit diverse industries. From prototype development to mass production, we have the capabilities to handle projects of any scale with precision and efficiency.

At DongGuan ChengYang, we understand the importance of quality and efficiency in CNC machining services for Louisiana. With a commitment to excellence and customer satisfaction, we aim to be the top choice for businesses in Louisiana seeking reliable and cost-effective CNC machining solutions.

CNC Machining services

Dongguan Chengyang are equipped with 3-axis, 4-axis, and 5-axis CNC milling machines, helps us to optimally machining parts ranging from elementary to sophisticated.

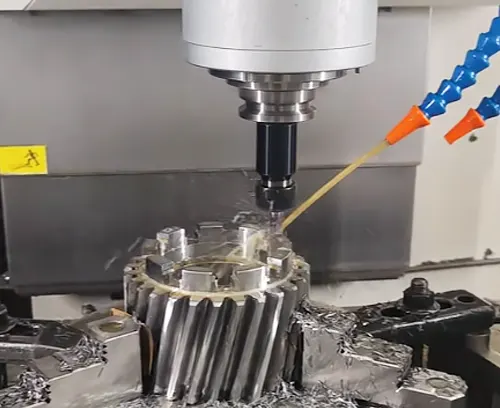

CNC Milling

Machining with precision using CNC equipment, ensuring top-quality components are delivered with speed and accuracy.

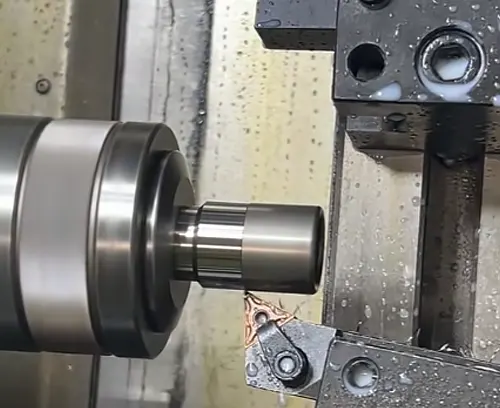

CNC Turnning

CY's CNC lathes, turning centers, and mill-turn equipment enable us withpresicion to produce a broad range of parts for every buyer.

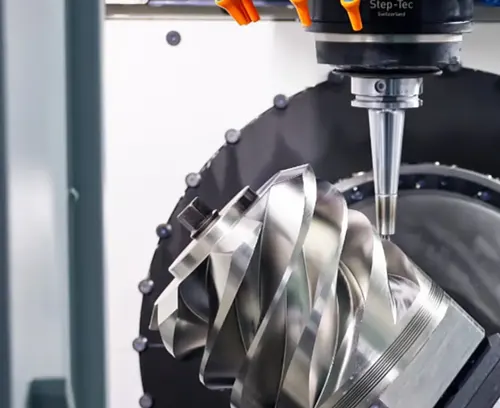

5 Axis CNC Milling

Provide 5-axis machining technology for intricate and precision-engineered components. Featuring quick production, it's perfect for exquisite designs.

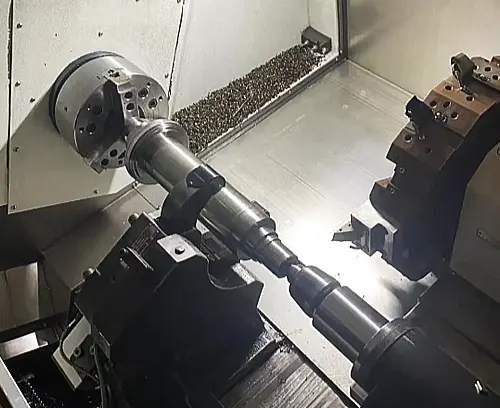

Precision Machining

Offer advanced manufacturing capabilities by aligning different manufacturing stages to boost performance, exactness, and shorten lead times, guaranteeing reliable, high-quality output.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

When a product is optimized for manufacturing early, DFM helps eliminate costly production issues.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

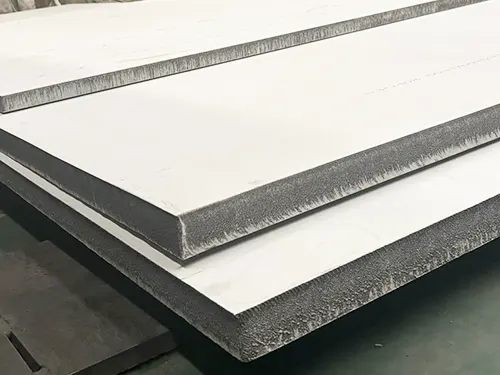

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.Instantly access quotes on over 100 types of metals and processing cost comparisons.

Aluminum

Aluminum is a widely used material in CNC machining due to its excellent machinability, lightweight nature, and corrosion resistance. It is a versatile material that is perfect for creating a wide range of products with precision and accuracy. Some common types of aluminum materials used in CNC machining include 6061 aluminum, known for its strength and weldability, 7075 aluminum, which is strong and has high stress ratings, and 2024 aluminum, valued for its high strength-to-weight ratio. These different types of aluminum offer unique properties that make them suitable for various applications in the manufacturing industry. When choosing the right type of aluminum for CNC machining, it is important to consider factors such as desired strength, machinability, and surface finish requirements.

Carbon Steel

Carbon steel is a widely used material in CNC machining due to its excellent strength, durability, and machinability. It is composed primarily of iron and carbon, with varying levels of other elements such as manganese, phosphorus, sulfur, and silicon. Common types of carbon steel used in CNC machining include AISI 1018, AISI 1045, AISI 1144, and AISI 12L14. AISI 1018 is a popular choice for general-purpose machining applications, while AISI 1045 is known for its higher carbon content and excellent heat treatment capabilities. AISI 1144 is ideal for parts requiring high precision and tight tolerances, while AISI 12L14, also known as leaded steel, offers improved machinability and chip control. When selecting a carbon steel for CNC machining, it is important to consider factors such as the desired strength, hardness, and surface finish of the final part.

Stainless Steel

Stainless steel is a popular material used in CNC machining due to its durability, corrosion resistance, and high strength. It is composed of iron, carbon, and various amounts of other elements such as chromium, nickel, and manganese, which give it its unique properties. Common types of stainless steel used in CNC machining include 303, 304, 316, and 17-4 PH. 303 is known for its ease of machining and good corrosion resistance. 304 is the most commonly used stainless steel and is suitable for a wide range of applications. 316 is highly corrosion resistant and is often used in marine environments. 17-4 PH offers high strength and hardness, making it ideal for applications requiring high wear resistance.

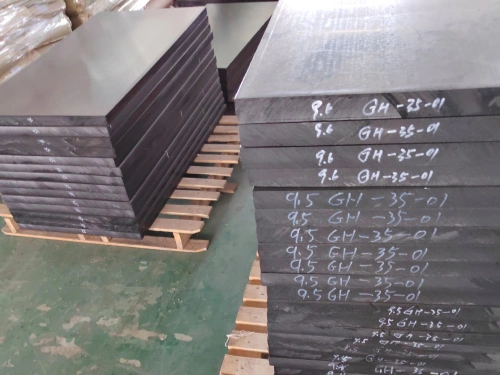

Tool Steel

Tool steel is a type of material commonly used in CNC machining due to its high strength, toughness, and wear resistance properties. It is often chosen for its ability to withstand high temperatures and harsh machining conditions. Some common types of tool steel used for CNC machining include A2 tool steel, D2 tool steel, M2 tool steel, and S7 tool steel. A2 tool steel is known for its excellent wear resistance and toughness, making it ideal for cutting tools. D2 tool steel is popular for its high wear resistance and excellent stability during heat treatment. M2 tool steel is preferred for its high-speed cutting capabilities and heat resistance. S7 tool steel is chosen for its shock resistance and high impact strength.

Brass

Brass is a commonly used material in CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appeal. It is an alloy of copper and zinc, typically containing around 60-70% copper. Brass is valued for its durability and ease of shaping, making it ideal for producing intricate parts with tight tolerances. Some common types of brass used in CNC machining include C36000 (free-cutting brass), C38500 (architectural bronze), and C46400 (naval brass). These different types of brass offer varying levels of strength, corrosion resistance, and machinability, allowing for versatility in machining applications. Overall, brass is a popular choice for CNC machining due to its combination of excellent properties and ease of use.

Copper

A Cooper for CNC machining is a cutting tool made from carbide or high-speed steel that is used to remove material from a workpiece during the machining process. Common types of materials that are used for Coopers in CNC machining include carbide, cobalt, and high-speed steel. Carbide Coopers are known for their hardness and resistance to wear, making them ideal for machining tough materials like stainless steel and titanium. Cobalt Coopers are used for machining high-temperature alloys, while high-speed steel Coopers are commonly used for general purpose machining of softer materials like aluminum and brass. Choosing the right type of Cooper for the material being machined is crucial for achieving high-quality and efficient results in CNC machining processes.

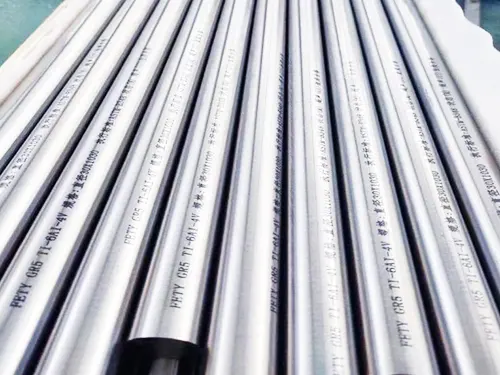

Titanium

Titanium is a popular material used in CNC machining due to its high strength, low weight, and excellent corrosion resistance. It is commonly used in aerospace, medical, and automotive industries for its exceptional properties. Some common types of materials used for CNC machining besides titanium include aluminum, stainless steel, brass, and copper. Aluminum is known for its lightweight and corrosion resistance, making it suitable for a wide range of applications. Stainless steel is favored for its durability and versatility, making it ideal for components that require strength and resistance to wear. Brass and copper are commonly used for their conductivity and aesthetic appeal in various precision machining applications.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic polymer used in CNC machining. Its advantages include high durability, impact resistance, and machinability, making it suitable for a wide range of applications. ABS is also known for its ability to be easily post-processed, allowing for painting, sanding, and gluing. However, ABS does have its disadvantages. It is prone to warping and shrinking, which can affect the dimensional accuracy of the final product. Additionally, ABS emits potentially harmful fumes when melted, requiring proper ventilation in the machining environment. Despite its drawbacks, ABS remains a popular choice in CNC machining for its versatility and cost-effectiveness.

PMMA

PMMA, or polymethyl methacrylate, is a transparent thermoplastic often used in CNC machining due to its excellent compatibility with high precision machining processes. Its advantages include a high tensile strength, good optical clarity, and resistance to sunlight and weathering. PMMA is also lightweight, making it ideal for applications where weight is a concern. Additionally, it can be easily molded and shaped into intricate designs with CNC machining. However, PMMA is prone to scratching and may not be as impact-resistant as other materials, such as polycarbonate. Care must be taken when handling and polishing PMMA to avoid creating any imperfections on the surface. Despite these drawbacks, PMMA remains a popular choice for CNC machining due to its versatility and aesthetic appeal.

PE

PE stands for “Programmable Electronics” in CNC machining. It is a system that allows operators to program cutting paths and tool movements, making the machining process more efficient and accurate. One advantage of PE is its ability to automate repetitive tasks, reducing human error and increasing productivity. Additionally, PE can store multiple programs, allowing for quick and easy access to different cutting routines. However, a disadvantage of PE is the initial cost of implementation and training. Companies may need to invest in specialized software and personnel to operate and maintain the system, which can be a significant expense. Despite this drawback, the benefits of PE in CNC machining can ultimately lead to higher quality parts and faster production times.

Nylon

Nylon is a commonly used material for CNC machining due to its versatility and strength. It is a thermoplastic material that can be easily machined to form intricate designs and shapes. One of the main advantages of using nylon for CNC machining is its high resistance to wear and abrasion, making it ideal for applications that require durable parts. Additionally, nylon has good chemical resistance and is lightweight, making it suitable for a wide range of industries. However, one disadvantage of nylon is that it tends to absorb moisture, which can affect its dimensional stability over time. It may also be prone to warping when exposed to high temperatures during the machining process.

PEEK

PEEK, which stands for Polyetheretherketone, is a high-performance thermoplastic material often used in CNC machining due to its excellent mechanical and chemical properties. Its main advantage lies in its exceptional resistance to high temperatures, chemicals, and wear, making it ideal for applications in industries such as aerospace, automotive, and medical. PEEK also offers good dimensional stability and low moisture absorption, ensuring precision and consistency in machining processes. However, one of the main disadvantages of PEEK is its high cost compared to other materials used in CNC machining. Additionally, PEEK can be difficult to machine due to its high temperature resistance, which can lead to tool wear and longer processing times.

PC

A PC for CNC machining is a personal computer that is used to control the operations of a computer numerical control (CNC) machine. The main advantage of using a PC for CNC machining is its ability to provide high precision and accuracy in manufacturing parts. With the use of specialized software, operators can easily create complex designs and program the machine to execute them with minimal errors. Additionally, PCs offer flexibility in terms of customization and can be easily integrated with other systems in a production line. However, a disadvantage of using a PC for CNC machining is the risk of system crashes or software malfunctions, which can lead to costly downtime and delays in production. It is important for manufacturers to have backup systems in place to mitigate these risks.

PP

PP, or polypropylene, is a commonly used material in CNC machining due to its versatile properties. One of the main advantages of using PP for CNC machining is its high chemical resistance, making it suitable for a wide range of applications. Additionally, PP is a lightweight material, making it easy to work with and reducing machining time. However, PP also has its disadvantages. One major drawback is its poor UV resistance, which means it may not be suitable for outdoor applications. Additionally, PP has lower strength compared to other engineering plastics, which may limit its use in applications requiring high strength or durability. Overall, while PP has its advantages, it is important to consider its limitations when choosing a material for CNC machining projects.

PET

PET, or Polyethylene Terephthalate, is a commonly used material in CNC machining due to its excellent mechanical properties and chemical resistance. PET is a versatile thermoplastic that can be easily machined to create precise and intricate parts. Its advantages include high tensile strength, low moisture absorption, and good dimensional stability. Additionally, PET is a cost-effective material that is readily available on the market. However, one major disadvantage of PET in CNC machining is its poor resistance to high temperatures, which can limit its applications in certain industries. Despite this drawback, PET remains a popular choice for CNC machining due to its overall performance and ease of use.

POM

POM, or Polyoxymethylene, is a type of engineering plastic commonly used in CNC machining. Its advantages include high strength, stiffness, and excellent dimensional stability, making it ideal for precise machining applications. POM also has good wear resistance and low coefficient of friction, which results in a smooth surface finish. However, POM is susceptible to environmental stress cracking and can degrade when exposed to certain chemicals. It also has poor UV resistance, which limits its outdoor applications. Despite these disadvantages, POM remains a popular choice for CNC machining due to its overall mechanical properties and ease of use in manufacturing processes.

PVC

PVC, or polyvinyl chloride, is a widely used material in CNC machining due to its affordability, easy machinability, and chemical resistance. It is a type of plastic that is commonly used in various industries for its versatility and low cost. One of the main advantages of using PVC for CNC machining is its ease of cutting, shaping, and milling, making it ideal for creating complex parts and prototypes. Additionally, PVC is lightweight and durable, making it suitable for a wide range of applications. However, PVC does have some disadvantages, such as its lower strength compared to metals like aluminum or steel, limiting its use in high-stress applications. Additionally, PVC can release toxic fumes when heated, requiring proper ventilation and safety precautions when machining.

Surface Finishes

We take pride in offering expert surface treatment services delivered by seasoned specialists.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is the act of cleaning teeth with a toothbrush and toothpaste to remove plaque and food particles. It is essential to maintain oral hygiene and prevent tooth decay and gum disease. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting is a method of propelling fine bits of material at high speeds to clean or etch a surface. It can remove paint, rust, and dirt effectively, making it popular in various industries. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves a series of acrobatic moves performed in rapid succession. It requires strength, flexibility, and coordination to execute flips, twists, and somersaults with precision. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is the process of refining a surface using abrasive materials to improve its appearance or functionality. It involves smoothing out imperfections and creating a smooth, glossy finish to enhance the overall aesthetics. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that enhances the surface of metals like aluminum through oxidation. This creates a durable, corrosion-resistant finish that also improves the metal's appearance and strengthens it. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form that involves the application of pigments on a surface to create a representation of an idea, emotion, or reality. It is a powerful means of expression and communication that has been practiced for centuries. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a chemical conversion coating used to add corrosion resistance, reduce light reflection, and enhance the appearance of steel and iron parts. It creates a black finish by converting the surface to magnetite. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process used to coat a metal object with a thin layer of another metal, typically to improve its appearance or protect it from corrosion. This technique is commonly used in industries such as automotive and electronics. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process in which fine powder particles are electrostatically charged and sprayed onto a workpiece. The piece is then heated, causing the powder to melt and form a hard, protective coating. This method is used in a variety of industries for its durability and environmentally friendly qualities. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine, also known as chromate conversion coating, is a chemical process that creates a protective layer on aluminum surfaces. This coating improves corrosion resistance and enhances adhesion for subsequent paint or coating applications. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a process that involves treating a metal surface in order to make it more corrosion-resistant. It typically involves the removal of free iron or other potential corrosion agents. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process that involves depositing a metal coating onto a surface through a chemical reaction, without the need for an electric current. This method is commonly used in industries for its even and uniform coating properties. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Louisiana, USA

Depend on our experienced experts to bring out the best in your product’s surface.

FAQ

Here, some of the most common questions about CNC machining services for Louisiana, USA. ” free to contact us if you have any question.”

Introduction

CNC machining services play a crucial role in the manufacturing industry, offering precision and efficiency in producing parts and components for a wide range of applications. For businesses in Louisiana, USA, accessing reliable CNC machining services is essential for staying competitive in the market. In this article, we will address some common questions related to CNC machining services for Louisiana businesses.

Q: What are CNC machining services?

A: CNC machining services involve using computer numerical control (CNC) machines to automate the manufacturing process of parts and components. These machines follow programmed instructions to cut, drill, mill, and shape materials like metal, plastic, and wood with high precision.

Q: How can CNC machining services benefit businesses in Louisiana?

A: CNC machining services offer increased efficiency, accuracy, and consistency in producing parts and components. This can result in cost savings, faster production times, and higher quality products for businesses in Louisiana.

Q: What industries can benefit from CNC machining services in Louisiana?

A: Industries such as aerospace, automotive, medical, and electronics can benefit from CNC machining services in Louisiana. These services are versatile and can cater to the specific needs of various industries.

Q: How can businesses in Louisiana find reliable CNC machining services?

A: Businesses in Louisiana can find reliable CNC machining services by conducting thorough research, checking customer reviews, and asking for samples of previous work from potential service providers.

Conclusion

Overall, CNC machining services are essential for businesses in Louisiana looking to stay competitive in the market. By understanding the benefits and capabilities of CNC machining services, businesses can make informed decisions when choosing a service provider for their manufacturing needs.