CNC machining services forUSA

Choose craftsmanship—order premium parts

Our CNC machining services, in USA , makes quality components for your demand.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

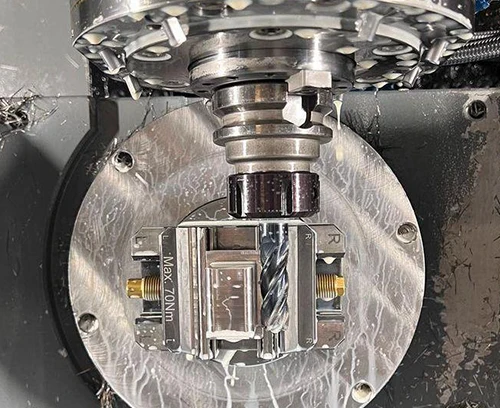

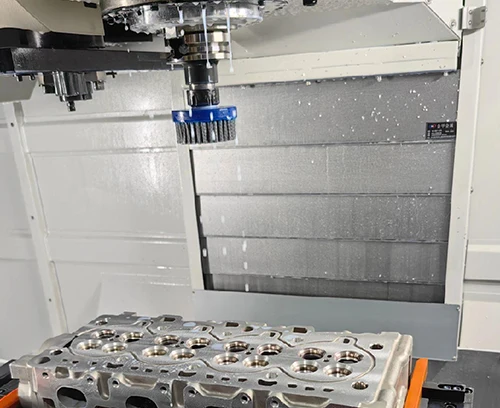

CNC Machining services

Dongguan Chengyang uses 3-axis, 4-axis and 5-axis CNC milling machines to easily process parts of varying difficulty. At the same time, with the help of CNC lathes, turning centers and turning-milling compound machines, we can process a variety of different plastic, metal and rubber parts.

CNC Milling

From fundamental 3-axis machining to complex 5-axis projects, our precision CNC milling brings your designs to life with exceptional accuracy and craftsmanship.

CNC Turnning

Our CNC turning capabilities ensure the production of highly accurate turned parts, no matter how complex the design. Get durable parts featuring flats, radial and axial holes, slots, and grooves—delivered in as fast as one day.

5 Axis CNC Milling

Achieve high precision and exceptional accuracy with our 5-axis CNC machining services, capable of producing intricate parts with extremely complex geometries. We offer tolerances as tight as 0.01mm and instant online CNC quotes.

Precision Machining

Precision machining utilizes advanced CNC technology to manufacture highly accurate parts essential for industries such as aerospace, medical devices, and electronics.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

Design for Manufacturing (DFM) optimizes a part or product for easier, cost-effective production. By refining the design early, manufacturers can reduce costs and prevent errors.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

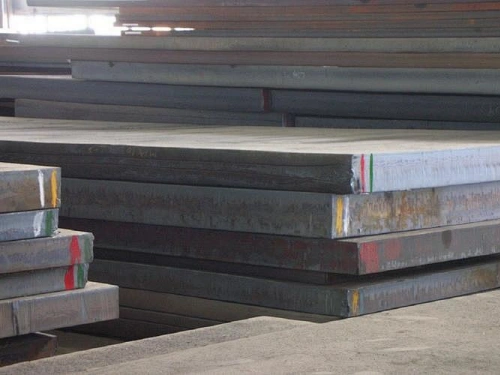

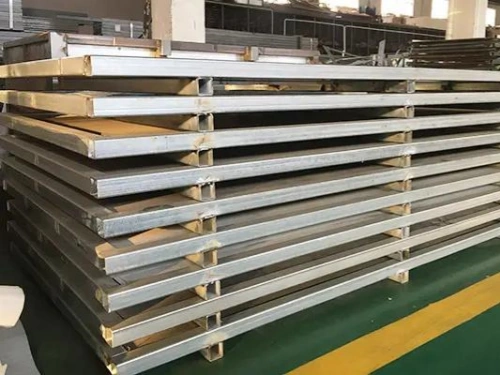

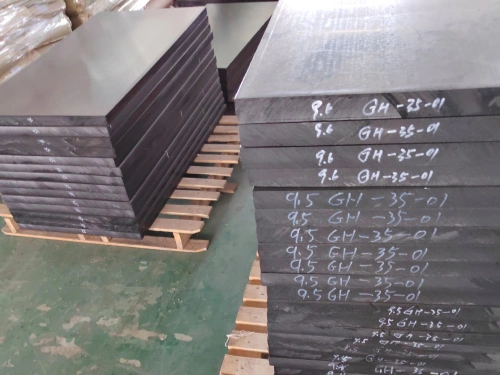

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.

Aluminum

Aluminum

Aluminum, valued for its combination of lightness and strength, offers increased durability without the addition of unnecessary weight. Its remarkable ductility allows for detailed shaping, making it ideal for complex designs.

Carbon Steel

Carbon Steel

Carbon steel is a type of steel with excellent mechanical properties and a wide range of applications. Through reasonable heat treatment processes and corrosion prevention measures, its performance can be further enhanced and its service life extended.

Stainless Steel

Stainless Steel

Stainless steel, renowned for its enduring quality and resistance to stains, ensures long-lasting use and maintains its appearance, even in harsh conditions.

Tool Steel

Tool Steel

Tool Steel, or tool steel, is a type of steel primarily used for manufacturing cutting tools, gauges, molds, and wear-resistant tools. It is characterized by its high hardness, ability to maintain hardness and red-hardness at high temperatures, high wear resistance, and adequate toughness.

Brass

Brass

Long-lasting, unique gold hue, robust, readily workable for intricate parts.

Copper

Copper

The advantages of copper are unmistakable: it possesses unparalleled electrical conductivity, high thermal efficiency, and natural corrosion resistance, ensuring long-lasting durability and superior performance across various manufacturing applications.

Titanium

Titanium

High conductivity for both heat and electricity, malleable, resistant to corrosion, ideal for complex shaping and bending processes.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS

ABS is a copolymer consisting of three monomers: acrylonitrile, butadiene, and styrene. The mix of these monomers gives ABS a distinct set of characteristics, such as high impact strength, satisfactory heat resistance, and outstanding dimensional stability.

PMMA

PMMA

PMMA, also referred to as acrylic, is a durable and transparent material that is resistant to UV radiation and weathering. Thanks to its appealing aesthetics, it can be readily colored, molded, and utilized in a wide range of construction applications.

PE

PE

Polyethylene (PE) is a widely utilized thermoplastic polymer renowned for its outstanding properties. This lightweight, resilient, and adaptable material finds extensive application in diverse fields, owing to its ease of processing into various shapes and sizes.

Nylon

Nylon

During machining, nylon, a synthetic thermoplastic polymer, necessitates careful attention to prevent overheating, as this can result in problems such as melting, distortion, or harm to the material.

PEEK

PEEK

PEEK (Polyetheretherketone) is a distinctive engineering plastic renowned for its exceptional qualities, such as resistance to high temperatures, self-lubricating capabilities, ease of fabrication, and superior mechanical strength.

PC

PC

Polycarbonate is a robust and durable plastic that possesses flame-resistant and antioxidant characteristics. It exhibits superior impact resistance, clarity, and mechanical attributes.

PP

PP

PP (Polypropylene) is noted for its exceptional chemical resistance, a high melting temperature, and its low density. When machining PP with a CNC machine, it is essential to employ a sharp tool with a large rake angle and a slow cutting speed. These precautions ensure that the material does not overheat and melt.

PET

PET

Polyethylene terephthalate (PET), a thermoplastic material, is a suitable choice for CNC milling and turning processes because of its excellent machinability and adaptability. With appropriate tooling and cutting settings, PET can be readily shaped and molded, rendering it perfect for producing prototypes, bespoke components, and containers via CNC machining.

POM

POM

POM(Polyoxymethylene) is a thermoplastic material known for its exceptional stiffness, low friction coefficient, ease of machining, and outstanding dimensional stability. However, working with POM can be difficult because of its high melting temperature and tendency to chip or crack if the cutting parameters are not precisely managed.

PVC

PVC

PVC is robust, long-lasting, and resistant to chemicals, weather conditions, and flame. However, machining it can generate hazardous dust and fumes that may pose a risk to workers’ safety. To ensure the safety of workers, it is essential to utilize appropriate safety gear and ventilation during the process.

Surface Finishes

Our experienced professionals specialize in product surface treatment.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is a surface treatment that grinds the workpiece to create decorative lines, enhancing its aesthetic appeal. | Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting uses high-speed sand flow to clean and roughen surfaces, ensuring desired cleanliness and texture. | All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling smooths surfaces, deburrs edges, and enhances uniformity by rotating materials with abrasive media. | All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing removes imperfections, smooths surfaces, and enhances appearance, creating a shiny, reflective finish. | All Materials | N/A | Smooth | |

| Anodizing | Anodizing enhances aluminum by adding a protective layer for improved corrosion resistance, hardness, and appearance. | Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Mount the product on a rotating bracket, secure it on the assembly line, and apply paint evenly. This improves texture but may increase scratch susceptibility. | All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide forms a protective film that enhances corrosion resistance, appearance, and reduces light reflection, ideal for steel and stainless steel. | Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating enhances function, aesthetics, and corrosion resistance, widely used in industries like automotive for chrome-plated steel parts. | Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating electrostatically applies dry powder to metal, then cures it with heat or UV light for a durable, attractive finish. | Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | An alodine finish forms a thin protective coating on aluminum, preventing corrosion and serving as a paint primer. | Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation improves stainless steel's corrosion resistance by immersing it in an acid solution, removing contaminants, and forming a protective oxide layer. | Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating deposits metal onto a substrate through a chemical reaction, creating a uniform, adherent coating without the need for an external electrical current. | Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

CNC machining services Locations Near Alabama, USA

Our experienced professionals specialize in product surface treatment.

FAQ

Here, some of the most common questions about CNC machining services for Alabama, USA. ” free to contact us if you have any question.”

FAQs about CNC Machining Services for USA

Q: What materials can be used in CNC machining services?

A: CNC machining services can work with a variety of materials including metals like aluminum, steel, and titanium, as well as plastics like ABS, PVC, and acrylic.

Q: What types of products can be created with CNC machining services?

A: CNC machining services can create a wide range of products including prototypes, custom parts, components for machinery, and even intricate jewelry pieces.

Q: How precise are CNC machining services?

A: CNC machining services are extremely precise, with the ability to create parts with tolerances as low as 0.001 inches.

Q: How long does it take to complete a CNC machining project?

A: The time it takes to complete a CNC machining project depends on the complexity of the design and the quantity of parts needed, but turnaround times can vary from a few days to a few weeks.

Q: Are CNC machining services cost-effective for small businesses?

A: CNC machining services can be cost-effective for small businesses, especially when it comes to creating prototypes or small production runs.

Q: Can CNC machining services handle large volume production?

A: Yes, CNC machining services can handle large volume production runs, making it a versatile option for businesses of all sizes.

Q: How do I choose the right CNC machining service for my project?

A: When choosing a CNC machining service, consider factors such as their experience, equipment capabilities, and customer reviews to ensure they can meet your project needs.

Q: What file formats are compatible with CNC machining services?

A: CNC machining services typically work with CAD files in formats like .STP, .IGES, and .DWG, but they may also accept other file types.

Q: Can CNC machining services provide design assistance?

A: Some CNC machining services offer design assistance to help optimize your designs for manufacturability and cost-effectiveness.

Q: Are there any limitations to what CNC machining services can create?

A: While CNC machining services are versatile, there may be limitations when it comes to the size of parts that can be produced or the complexity of certain designs.

Aluminum

Aluminum Carbon Steel

Carbon Steel Stainless Steel

Stainless Steel Tool Steel

Tool Steel Brass

Brass Copper

Copper Titanium

Titanium ABS

ABS PMMA

PMMA PE

PE Nylon

Nylon PEEK

PEEK PC

PC PP

PP PET

PET POM

POM PVC

PVC