CNC machining services forUSA

Equip your project with quality components

CY's CNC machining services, in USA , makes precision parts for your needs.

Welcome to DongGuan ChengYang, a leading provider of CNC machining services for Colorado. With state-of-the-art technology and a team of experienced professionals, we are dedicated to delivering high-quality machining services to meet the needs of our customers in Colorado.

Our precision CNC machining capabilities allow us to produce complex components with tight tolerances, ensuring the highest level of accuracy and consistency in every project we undertake. Whether you require prototyping, production runs, or custom parts, our team is equipped to handle a wide range of machining projects for various industries in Colorado.

At DongGuan ChengYang, we understand the importance of delivering reliable and efficient CNC machining services to our customers in Colorado. With our commitment to excellence and customer satisfaction, you can trust us to provide the highest quality machining solutions that meet your specific requirements and exceed your expectations. Contact us today to learn more about our CNC machining services for Colorado.

CNC Machining services

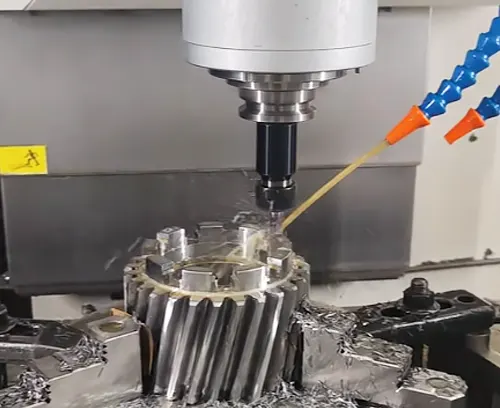

Dongguan Chengyang are equipped with 3-axis, 4-axis, and 5-axis CNC milling machines, helps us to optimally processing part ranging from elementary to sophisticated.

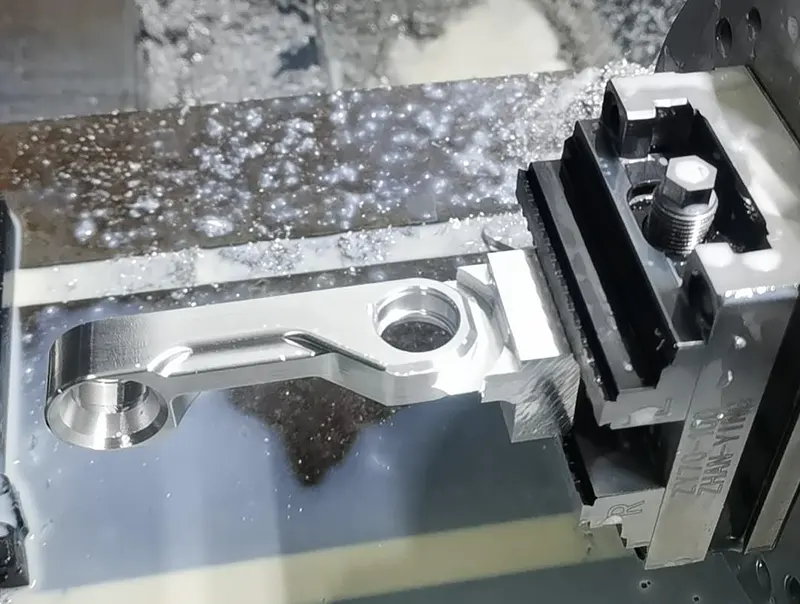

CNC Milling

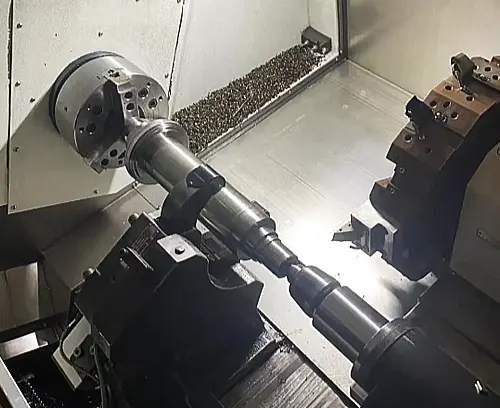

Machining with precision using CNC equipment, producing high-performance parts efficiently for our clients.

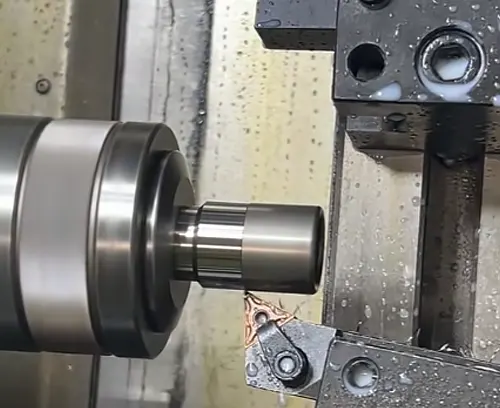

CNC Turnning

CY's CNC lathes, turning centers, and mill-turn equipment enable us withpresicion to fabricate a broad range of parts for every client.

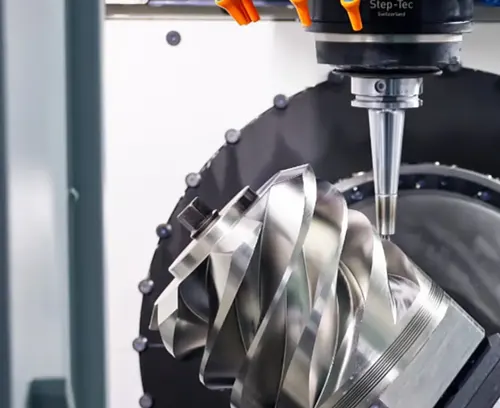

5 Axis CNC Milling

Offer 5-axis machining technology for intricate and precision-engineered components. Featuring faster processing, it's perfect for complex designs.

Precision Machining

Provide expert machining solutions by combining several production phases to boost performance, exactness, and shorten lead times, guaranteeing reliable, high-quality output.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

A DFM-driven approach results in a well-optimized design that’s simple and economical to produce.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

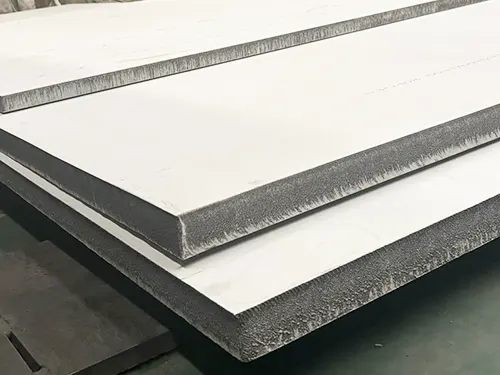

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.We provide fast quotes on over 100 metal types and help you evaluate material processing costs.

Aluminum

Aluminum is a popular material used in CNC machining due to its lightweight nature, strong durability, and excellent machinability. It is commonly chosen for a wide range of applications in various industries such as automotive, aerospace, and electronics. Some common types of aluminum materials used in CNC machining include 6061 aluminum, known for its high strength and weldability; 7075 aluminum, which offers excellent strength-to-weight ratio; and 2024 aluminum, preferred for its good machinability and fatigue resistance. These materials are widely used for manufacturing components, prototypes, and custom parts with precision and efficiency in CNC machining processes.

Carbon Steel

Carbon steel is a widely used material in CNC machining due to its high strength, durability, and cost-effectiveness. It is an alloy of iron and carbon, with other elements such as manganese, silicon, and copper added for specific properties. Common types of carbon steel for CNC machining include AISI 1018, 1045, and 1095. AISI 1018 is a low carbon steel with good machinability and weldability, making it suitable for a wide range of applications. AISI 1045 is a medium carbon steel known for its toughness and strength, ideal for parts requiring high impact resistance. AISI 1095 is a high carbon steel often used for springs and cutting tools, known for its hardness and edge retention.

Stainless Steel

Stainless steel is a versatile and popular material used in CNC machining due to its strong corrosion resistance, durability, and high strength. Its composition includes a significant amount of chromium, which forms a protective oxide layer on its surface, making it resistant to rust and staining. Common types of stainless steel used in CNC machining include 303, 304, and 316. 303 stainless steel is easy to machine and ideal for parts requiring extensive machining. 304 stainless steel is widely used for its excellent corrosion resistance and weldability. 316 stainless steel is known for its superior strength and temperature resistance, making it suitable for applications in harsh environments. Overall, stainless steel is a reliable and cost-effective option for a wide range of CNC machining projects.

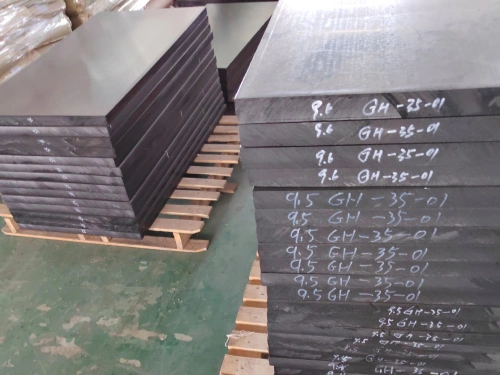

Tool Steel

Tool steel is a type of material commonly used in CNC machining due to its high resistance to wear, deformation, and heat. Common types of tool steel include H13, D2, A2, M42, and O1. H13 tool steel is known for its hot hardness and excellent wear resistance, making it suitable for applications such as die casting molds and extrusion tools. D2 tool steel is highly wear-resistant and is often used in forming dies and punches. A2 tool steel is an air-hardening, cold work steel that offers good toughness and wear resistance. M42 tool steel is known for its high hardness and wear resistance, making it suitable for high-speed cutting tools. O1 tool steel is a general-purpose oil-hardening steel often used for forming dies and punches.

Brass

Brass is a popular material used in CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appeal. It is a copper-zinc alloy that offers good thermal and electrical conductivity, making it suitable for a wide range of applications. Some common types of brass materials used in CNC machining include C360, C932, C360, and C280. These different grades offer varying levels of strength, durability, and corrosion resistance to suit the specific requirements of the project at hand. Overall, brass is a versatile material that is ideal for creating intricate and precise components in CNC machining processes.

Copper

Cooper, commonly known as copper in the world of CNC machining, is a popular material choice due to its excellent conductivity and corrosion resistance. It is a soft metal that is easily malleable and can be machined into intricate shapes with high precision. Some common types of materials used in CNC machining with copper include copper alloys such as brass and bronze, as well as pure copper. Brass is a versatile material that is often used in decorative applications, while bronze is known for its strength and durability. Pure copper is typically used for electrical applications due to its superior conductivity. These materials provide a wide range of options for CNC machining projects requiring copper components.

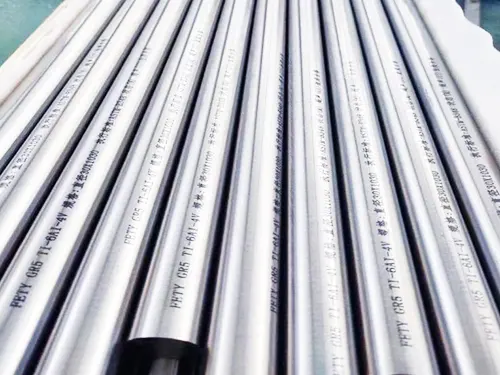

Titanium

Titanium is a commonly used metal in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. This versatile material is known for its high strength, low density, and ability to withstand high temperatures, making it ideal for a wide range of applications in industries such as aerospace, medical, automotive, and more. Some common types of titanium alloys used in CNC machining include Grade 5 (Ti-6Al-4V), Grade 2 (Ti-6Al-4V), and Grade 23 (Ti-6Al-4V-ELI). These materials offer different properties and characteristics, allowing for optimal performance and precision in machining processes. Overall, titanium is a valuable material in CNC machining that offers exceptional durability and reliability.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic material used in CNC machining for its excellent mechanical properties, impact resistance, and machinability. Its advantage lies in its high strength, good dimensional stability, and resistance to chemicals and impacts. ABS is also relatively easy to cut, mill, and drill, making it a popular choice for a variety of applications. However, one of the main disadvantages of ABS is its tendency to warp and shrink during the cooling process, leading to potential inaccuracies in the final product. Additionally, ABS is prone to degradation when exposed to UV light, limiting its outdoor applications. Despite its drawbacks, ABS remains a versatile material for CNC machining due to its favorable combination of strength, flexibility, and cost-effectiveness.

PMMA

PMMA, also known as polymethyl methacrylate, is a widely used material in CNC machining due to its high transparency, light weight, and impact resistance. One of the main advantages of using PMMA for CNC machining is its ability to be easily machined into complex shapes with high precision. Additionally, PMMA is known for its resistance to yellowing over time, making it a popular choice for applications requiring optical clarity. However, PMMA does have its drawbacks, including its tendency to scratch easily and its poor resistance to certain chemicals. It is important to consider these limitations when choosing PMMA for CNC machining projects to ensure the desired results are achieved.

PE

PE for CNC machining stands for Programmable Electronic Control. It refers to the computerized control system that operates CNC machines. The advantage of PE for CNC machining is the precision and accuracy it offers in creating complex and intricate parts. This technology allows for consistent and repeatable results, reducing the likelihood of errors and minimizing material waste. Additionally, PE for CNC machining allows for increased production efficiency and faster turnaround times. However, a disadvantage of PE for CNC machining is the initial investment required for purchasing and implementing this technology. Training operators to use the software and programming can also be time-consuming. Despite these drawbacks, the benefits of PE for CNC machining make it a valuable tool for manufacturers seeking high-quality and efficient production processes.

Nylon

Nylon is a commonly used material for CNC machining due to its excellent mechanical properties and versatility. Its advantages include high strength, flexibility, and impact resistance, making it suitable for a wide range of applications. Nylon is also known for its ability to be easily machined and has good chemical resistance. However, some disadvantages of using nylon for CNC machining include its tendency to absorb moisture, which can affect its dimensional stability and lead to warping or swelling. Additionally, nylon can be prone to wear and tear over time, requiring regular maintenance and potentially increasing production costs. Despite these drawbacks, nylon remains a popular choice for CNC machining due to its overall performance and affordability.

PEEK

PEEK, or polyether ether ketone, is a high-performance thermoplastic material that is commonly used in CNC machining due to its excellent mechanical properties and resistance to chemicals, high temperatures, and wear. One of the main advantages of using PEEK for CNC machining is its exceptional strength and stiffness, making it ideal for applications where durability and mechanical performance are crucial. Additionally, PEEK has a low coefficient of friction, which results in reduced wear on cutting tools and machinery, leading to longer tool life and improved machining precision. However, one major disadvantage of PEEK is its high cost compared to other materials, which can make it less cost-effective for some projects. Additionally, PEEK has poor thermal conductivity, which can result in heat buildup during machining, potentially leading to thermal distortion or damage to the material.

PC

A PC for CNC machining, commonly referred to as a Personal Computer Numerical Control, is a computer system that enables the control of machinery and tools in manufacturing processes. The main advantage of using a PC for CNC machining is the ability to program and control complex operations with precision and accuracy. This leads to increased efficiency, productivity, and reduced human error in the manufacturing process. However, a disadvantage of using a PC for CNC machining is the initial investment cost in acquiring the hardware and software needed for programming and controlling the machinery. Additionally, maintenance and technical expertise are required to ensure optimal performance of the PC for CNC machining system. Overall, the advantages of utilizing a PC for CNC machining outweigh the disadvantages, making it a valuable tool in the manufacturing industry.

PP

PP for CNC machining stands for Polypropylene, a type of plastic widely used in manufacturing for its excellent balance of properties. One advantage of using PP for CNC machining is its high chemical resistance, making it suitable for applications where exposure to harsh chemicals is a concern. Additionally, PP is known for its low cost, making it an affordable option for producing parts. However, a major disadvantage of PP is its poor resistance to UV light, which can cause it to degrade over time when exposed to sunlight. PP also has a relatively low strength compared to other materials, so it may not be suitable for applications requiring high strength or durability. Overall, PP for CNC machining offers a cost-effective and chemically resistant solution for many manufacturing needs.

PET

PET, or Polyethylene terephthalate, is a commonly used material in CNC machining. Its advantage lies in its excellent chemical resistance, making it suitable for a wide range of applications. PET is also known for its high strength and durability, making it an ideal choice for parts that require precision and reliability. However, PET does have some disadvantages. It can be more difficult to machine compared to other materials, leading to longer processing times and potentially higher costs. Additionally, PET is sensitive to high temperatures, which can limit its use in certain applications. Overall, while PET offers many benefits for CNC machining, it is important to consider its limitations when choosing a material for a specific project.

POM

POM, or Program Order Management, is a system employed in CNC machining to organize and schedule work orders efficiently. Its primary advantage lies in its ability to prioritize jobs based on criteria such as due dates, machine availability, and material availability. This helps to streamline production processes, reduce downtime, and optimize resource allocation. However, one significant disadvantage of POM is that it can be complex to set up and maintain, requiring specialized training and ongoing management. Additionally, if not properly configured, POM may lead to inefficiencies and disruptions in the workflow. Despite this drawback, the overall benefits of implementing POM in CNC machining far outweigh the challenges, making it an essential tool for maximizing productivity and profitability in manufacturing operations.

PVC

PVC, or polyvinyl chloride, is a popular material used in CNC machining due to its affordability, ease of fabrication, and resistance to various chemicals. Its advantages include excellent dimensional stability, low moisture absorption, and good impact strength. PVC is also lightweight and easy to machine, making it a versatile option for various applications. However, PVC does have some disadvantages such as low heat resistance, poor UV stability, and limited temperature range. Additionally, PVC can release harmful fumes when machined at high speeds, requiring proper ventilation during the machining process. Despite its drawbacks, PVC remains a commonly used material in CNC machining for its cost-effectiveness and ease of use.

Surface Finishes

Every product is treated by our experienced staff to ensure a flawless finish.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is the act of using a toothbrush to clean teeth and gums. It is essential in maintaining good oral hygiene by removing food particles, plaque, and bacteria that can lead to tooth decay and gum disease. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sand blasting is a process used to smooth, shape, or clean surfaces by forcibly propelling abrasive material against them at high speeds. It is commonly used in industrial, automotive, and construction applications. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves executing a series of acrobatic movements in quick succession. It requires strength, flexibility, and coordination to perform flips, twists, and somersaults with precision. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a finishing process that smooths and refines a surface to improve its appearance or functionality. It involves using abrasives like sandpaper or compounds to remove imperfections and achieve a desired level of shine. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that enhances the corrosion resistance of metal, typically aluminum. It involves creating a durable oxide layer on the surface through controlled oxidation, resulting in increased durability and aesthetic appeal. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form used to express ideas, emotions, and aesthetics through the application of pigments to a surface. It involves a wide range of techniques and styles, making it a versatile and impactful form of artistic expression. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a conversion coating applied to ferrous materials through a chemical reaction, creating a dark, durable finish. This process enhances corrosion resistance and provides a decorative appearance to various metal surfaces. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process of depositing a thin layer of metal onto a conductive surface using electrical currents. This technique is commonly used for enhancing metal objects, preventing corrosion, and improving conductivity. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process that uses finely ground particles of pigment and resin to create a durable and protective coating on a variety of materials. This coating is applied as a free-flowing powder and is then cured under heat, resulting in a smooth and uniform finish. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine is a chemical conversion coating used on aluminum and other metals to enhance corrosion resistance and improve paint adhesion. It creates a protective barrier that also improves conductivity. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a process used to protect metal surfaces from corrosion. It involves the formation of a thin layer of oxide that acts as a barrier against harmful environments, increasing the material's lifespan and durability. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process in which a metal coating is deposited onto a surface without the need for an external electrical current. This method relies on a series of chemical reactions to evenly coat the substrate with the desired metal. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Colorado, USA

Our team of seasoned professionals excels in surface treatment for all types of products.

FAQ

Here, some of the most common questions about CNC machining services for Colorado, USA. ” free to contact us if you have any question.”

FAQ for CNC Machining Services in Colorado, USA

Q: What is CNC machining?

A: CNC machining is a process in which computer-aided design (CAD) software is used to control and manipulate precision cutting tools to create custom parts and components.

Q: What materials can be used in CNC machining?

A: CNC machining services in Colorado can work with a variety of materials including metals like aluminum, steel, and titanium, as well as plastics and wood.

Q: How accurate is CNC machining?

A: CNC machining is known for its high precision and accuracy, with tolerances as tight as +/- 0.005 inches depending on the specific machine and tooling used.

Q: What industries can benefit from CNC machining services?

A: Industries such as aerospace, automotive, medical, and electronics rely on CNC machining services to produce complex and detailed parts with consistency and efficiency.

Q: How long does a CNC machining project typically take?

A: The timeline for a CNC machining project can vary depending on the complexity of the parts and the materials being used, but projects are usually completed within a few days to a few weeks.

Q: Can CNC machining services handle prototypes and small production runs?

A: Yes, CNC machining services in Colorado are well-equipped to handle prototypes as well as small to medium production runs with quick turnaround times.

Q: Are there any design limitations with CNC machining?

A: While CNC machining is incredibly versatile, there are limitations to consider such as the size and shape of the part, as well as the complexity of the design.

Q: How can I get a quote for CNC machining services?

A: You can easily get a quote for CNC machining services in Colorado by providing detailed drawings or 3D models of your parts along with the desired materials and quantities.

Q: What quality control measures are in place for CNC machining projects?

A: CNC machining services often have rigorous quality control processes in place to ensure that each part meets the required specifications and standards before it is delivered to the customer.

Q: Are there any additional services offered along with CNC machining?

A: Some CNC machining services in Colorado may offer additional services such as finishing, assembly, and packaging to provide a one-stop solution for your manufacturing needs.

Conclusion

Overall, CNC machining services in Colorado offer a wide range of capabilities for industries looking to produce custom parts with precision and efficiency. By understanding the basics of CNC machining and the services available, you can make informed decisions for your manufacturing projects. Whether you need prototypes, small production runs, or complex components, CNC machining services can help bring your designs to life.