CNC machining services forUSA

Choose craftsmanship—order premium parts

Our CNC machining services, in USA , makes high quality components for your demand.

We are DongGuan ChengYang, a machining service provider specializing in CNC machining services for Indiana. With years of experience and a team of skilled technicians, we are dedicated to providing high-quality machining services to meet the needs of our clients in Indiana. Our state-of-the-art equipment and precision technology allow us to deliver precise and efficient CNC machining solutions for a wide range of industries.

At DongGuan ChengYang, we understand the importance of accuracy and reliability in CNC machining services for Indiana. Whether you are in the automotive, aerospace, or medical industry, we have the expertise and capabilities to handle your machining needs with precision and efficiency. Our commitment to quality and customer satisfaction sets us apart as a trusted partner for CNC machining services in Indiana.

From prototyping to full-scale production, DongGuan ChengYang is your go-to source for CNC machining services in Indiana. Contact us today to learn more about how we can help you with your machining needs and discover the difference that our expertise and dedication can make for your business.

CNC Machining services

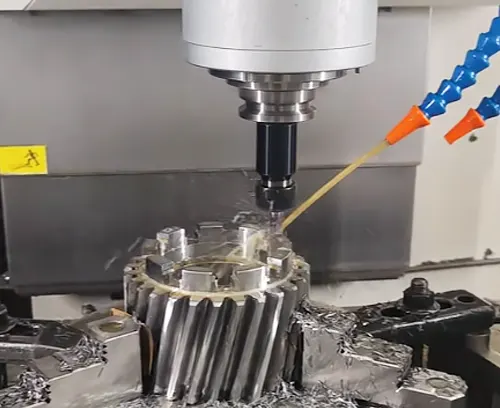

We brings together the power of 3-axis, 4-axis, and 5-axis CNC milling machines, helps us to skillfully handle parts ranging from straightforward to intricate.

CNC Milling

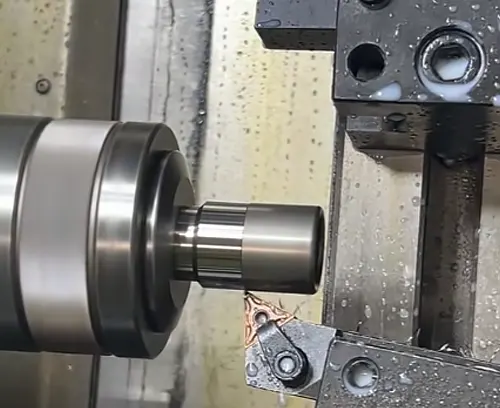

Utilizing both CNC technologies for versatile production, ensuring top-quality components are delivered with speed and accuracy.

CNC Turnning

CY's CNC lathes, turning centers, and mill-turn equipment enable us withhigh quality to construct a broad range of components for every buyer.

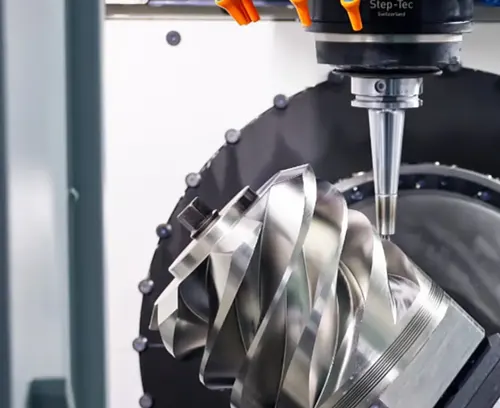

5 Axis CNC Milling

Offer 5-axis machining solutions for complicated and exacting parts. Featuring rapid machining, it's perfect for exquisite designs.

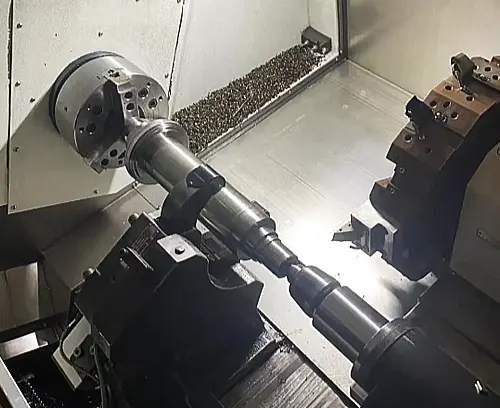

Precision Machining

Execute top-tier machining services by streamlining diverse operations to enhance productivity, accuracy, and speed up delivery, guaranteeing reliable, high-quality output.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

Design for Manufacturing involves early-stage design improvements that lead to smoother, more cost-effective production processes.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

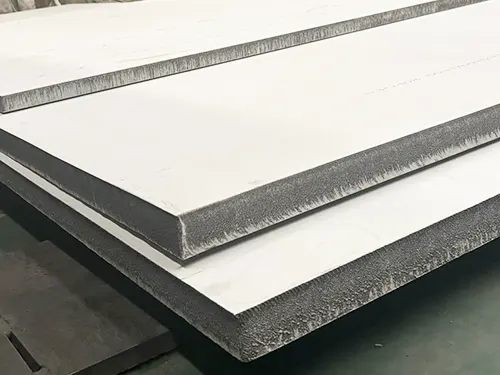

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.Compare material processing costs and get real-time quotes on 100+ metal options.

Aluminum

Aluminum is a widely used material in CNC machining due to its excellent machinability, lightweight properties, and corrosion resistance. It is often chosen for its affordability compared to other metals, making it a popular choice for a wide range of industries. Some common types of aluminum materials used in CNC machining include 6061 aluminum, known for its good strength and weldability; 7075 aluminum, which is highly resistant to stress and corrosion; and 2024 aluminum, favored for its high strength-to-weight ratio and good machinability. These different types of aluminum offer varying properties and characteristics that can be tailored to specific machining needs and applications.

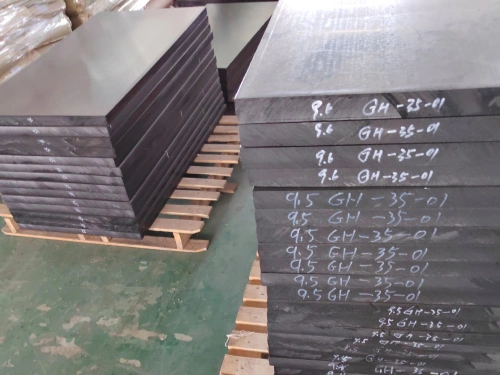

Carbon Steel

Carbon steel is a popular material used in CNC machining due to its high strength, durability, and cost-effectiveness. It is an alloy of iron with carbon content typically ranging between 0.05% and 2.0%. Common types of carbon steel used in CNC machining include:

1. Low carbon steel (mild steel) – easy to machine, form, and weld

2. Medium carbon steel – stronger and harder than low carbon steel

3. High carbon steel – has high strength and wear resistance but lower ductility

4. Tool steel – designed for making tools and dies, with high hardness and abrasion resistance.

These types of carbon steel offer a wide range of mechanical properties, making them suitable for various CNC machining applications.

Stainless Steel

Stainless steel is a versatile material commonly used in CNC machining due to its exceptional strength, durability, and resistance to corrosion. It is a type of steel alloy containing a minimum of 10.5% chromium, which forms a protective layer on its surface, making it impervious to rust and staining. Some common types of stainless steel used in CNC machining include: 1. 303 Stainless Steel, known for its excellent machinability and good resistance to corrosion; 2. 304 Stainless Steel, a widely used grade with high resistance to corrosion and excellent weldability; 3. 316 Stainless Steel, known for its superior corrosion resistance, particularly in harsh environments; 4. 17-4 Stainless Steel, a precipitation-hardening grade with high strength and excellent corrosion resistance. This variety of stainless steel options makes it a popular choice for CNC machining applications in various industries.

Tool Steel

Tool steel is a type of carbon and alloy steel that is specifically designed for use in manufacturing tools and dies for machining and shaping operations. It is highly resistant to abrasion, wear, and heat, which makes it a popular choice for CNC machining applications. Some common types of tool steel used for CNC machining include D2 tool steel, which is known for its high wear resistance and toughness, M2 tool steel, which is ideal for high-speed cutting applications, and A2 tool steel, which is valued for its excellent resistance to deformation and cracking. Other popular types of tool steel for CNC machining include O1, S7, and H13, each with its own unique properties and benefits for specific machining needs.

Brass

Brass is a commonly used material in CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appeal. It is a metallic alloy made up of copper and zinc, typically containing around 60-70% copper and 30-40% zinc. Brass is often chosen for CNC machining applications because it produces clean, precise cuts and finishes well. Some common types of brass materials used in CNC machining include C360, C353, and C464. C360 brass, also known as free machining brass, is popular for its high cutting speed and easy formability. C353 brass, on the other hand, is preferred for its excellent electrical conductivity. C464 brass, also known as naval brass, is often chosen for its superior corrosion resistance in marine environments.

Copper

Copper is commonly used in CNC machining for its excellent electrical conductivity, corrosion resistance, and thermal conductivity. It is an ideal choice for the production of electrical components, heat sinks, and various precision parts. Some common types of materials used in CNC machining with copper include copper alloys such as brass, bronze, and beryllium copper. Brass, a combination of copper and zinc, is well-suited for creating decorative pieces and fittings. Bronze, composed of copper and tin, is often used for artistic sculptures and musical instruments. Beryllium copper, known for its high strength and fatigue resistance, is utilized in aerospace and defense industries for creating components that require durability and reliability.

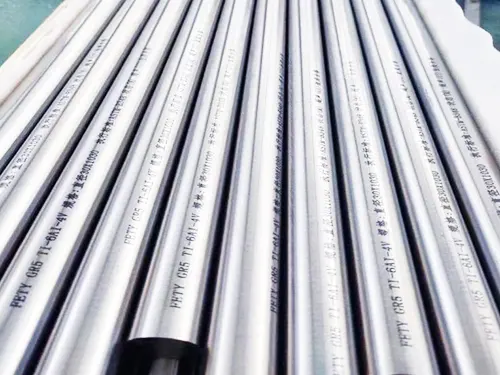

Titanium

Titanium is a popular material used in CNC machining due to its strength, corrosion resistance, and lightweight properties. It is commonly used in industries such as aerospace, medical, and automotive for producing precision parts and components. Some common types of materials used in CNC machining alongside titanium include aluminum, stainless steel, brass, and copper. These materials offer different strengths, hardness, and corrosion resistance, making them suitable for a variety of applications in manufacturing. However, titanium stands out for its high strength-to-weight ratio and biocompatibility, making it a versatile choice for producing high-quality, durable parts in CNC machining processes.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic material used in CNC machining. It is known for its high strength, impact resistance, and ability to be easily machined to tight tolerances. The advantages of using ABS for CNC machining include its superior surface finish, good dimensional stability, and excellent durability. ABS also has good chemical resistance and can be easily post-processed by painting, plating, or adding textures. However, one major disadvantage of ABS is its tendency to warp when exposed to high temperatures, which can lead to warping or misalignment of the final product. Additionally, ABS can release toxic fumes when machined at high speeds, so proper ventilation is necessary when working with this material.

PMMA

PMMA, or polymethyl methacrylate, is a versatile thermoplastic material often used in CNC machining due to its excellent clarity, glass-like appearance, and ease of machining. One of the main advantages of PMMA for CNC machining is its ability to be easily machined into complex shapes with high precision, making it ideal for various applications such as automotive parts, signage, and medical devices. Additionally, PMMA is highly resistant to scratches and UV light, ensuring long-lasting durability. However, one disadvantage of PMMA is its tendency to crack or shatter under excessive stress or impact, limiting its use in applications that require high impact resistance. Despite this drawback, PMMA remains a popular choice for CNC machining due to its aesthetic appeal and machinability.

PE

PE, or Programmed Evaluations, in CNC machining refer to a series of predefined measurements and evaluation parameters used to control the cutting process. The main advantage of PE is its ability to automate the manufacturing process, ensuring consistent and accurate results. This not only increases productivity but also reduces the chances of human error. Additionally, PE allows for greater flexibility in setting parameters and making adjustments during the machining process. However, a major disadvantage is that PE can be complex to set up and require detailed programming knowledge. Also, if the parameters are not properly optimized, it can result in inefficiency or even damage to the workpiece. Overall, while PE offers many benefits, it is important to weigh these against the potential challenges in implementation.

Nylon

Nylon is a popular material used in CNC machining due to its versatility and durability. It is a synthetic polymer that is known for its excellent mechanical properties, including high strength, flexibility, and resistance to abrasion. Nylon is also relatively lightweight, making it ideal for a wide range of applications, such as automotive parts, consumer goods, and medical devices. One of the main advantages of using nylon for CNC machining is its ability to be easily machined into complex shapes with tight tolerances. However, nylon does have some disadvantages, including its tendency to absorb moisture, which can affect its dimensional stability and mechanical properties. Additionally, nylon can be prone to warping or shrinking during the machining process, so careful consideration must be taken when working with this material.

PEEK

PEEK, or polyetheretherketone, is a high-performance thermoplastic material often used in CNC machining due to its excellent mechanical and thermal properties. Its advantages include high strength, stiffness, and chemical resistance, making it ideal for applications that require durability and reliability. Additionally, PEEK has low moisture absorption and is biocompatible, making it suitable for medical implants and aerospace components. However, PEEK can be challenging to machine due to its high melting point and abrasive nature, which can increase tool wear and machining costs. Additionally, PEEK can be prone to warping and dimensional instability if not properly controlled during the machining process. Overall, while PEEK offers many benefits, it is important to carefully consider the potential challenges when selecting this material for CNC machining projects.

PC

PC for CNC machining refers to the use of a computer to control the operations of a CNC machine. This technology allows for precise and efficient manufacturing processes in industries such as aerospace, automotive, and electronics. One of the key advantages of using a PC for CNC machining is the ability to program complex designs with high levels of accuracy. Additionally, PCs offer the flexibility to make quick adjustments to programs, reducing production time and costs. However, there are also disadvantages to consider. The initial investment in software and training can be expensive, and there is a learning curve for operators to become proficient in utilizing the software effectively. Additionally, PC systems may be vulnerable to cyber threats and require regular maintenance to ensure optimal performance.

PP

PP, or polypropylene, is a commonly used material in CNC machining due to its versatility and affordability. One of the main advantages of using PP for CNC machining is its lightweight nature, which allows for ease of transportation and manipulation during the manufacturing process. Additionally, PP is resistant to chemicals and moisture, making it ideal for applications that require a high level of durability. However, one disadvantage of PP is its lower strength compared to other materials, such as aluminum or steel, which may limit its use in applications that require higher load-bearing capabilities. Despite this drawback, PP remains a popular choice for CNC machining due to its cost-effectiveness and overall performance in various industries.

PET

PET stands for Polyethylene Terephthalate, which is a type of plastic commonly used in CNC machining. One of the main advantages of using PET for CNC machining is its excellent dimensional stability and resistance to chemicals, making it ideal for producing parts that require high precision and durability. PET is also lightweight, making it a popular choice for industries where weight is a concern. However, one disadvantage of using PET for CNC machining is its limited heat resistance compared to other plastics, which can lead to deformation or warping if exposed to high temperatures during the machining process. Additionally, PET can be more expensive than other types of plastics, which may be a drawback for businesses looking to keep costs low.

POM

POM stands for Polyoxymethylene, a type of thermoplastic material commonly used in CNC machining. One of the main advantages of POM is its high mechanical strength, stiffness, and excellent wear resistance, making it ideal for applications where durability is crucial. POM also possesses good dimensional stability and resistance to chemicals, making it suitable for a wide range of industries. However, one disadvantage of POM is its tendency to degrade under continuous exposure to UV light, which can limit its outdoor use. Additionally, POM can be challenging to bond with other materials, requiring specialized adhesives or surface treatments. Overall, POM offers a balance of properties that make it a valuable material for CNC machining, but its limitations should be considered when choosing the right material for a specific application.

PVC

PVC, short for Polyvinyl Chloride, is a popular choice for CNC machining due to its versatility, cost-effectiveness, and ease of fabrication. Its advantages include high chemical resistance, durability, and ability to be easily molded and machined to precise specifications. PVC also has excellent electrical insulating properties, making it suitable for a variety of applications in different industries. However, PVC does have some disadvantages, such as limited temperature resistance, poor UV stability, and the emission of harmful gases when heated during processing. Additionally, PVC can be difficult to recycle, posing environmental concerns. Overall, PVC remains a common material for CNC machining due to its favorable properties, but it is important to consider both its advantages and disadvantages when selecting it for a specific project.

Surface Finishes

We specialize in enhancing product surfaces through professional treatment services.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is the act of cleaning teeth using a toothbrush and toothpaste. It helps remove plaque, prevent cavities, and maintain good oral hygiene. It should be done at least twice a day for optimal dental health. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sand blasting is a technique used to clean, polish, or shape a hard surface by propelling solid particles across it at high speeds using compressed air. It is commonly used in industrial applications for surface preparation and finishing. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics characterized by acrobatic moves performed seamlessly in a series. It includes flips, twists, and somersaults executed with precision and control. Tumbling requires strength, flexibility, and skill. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a process of refining a surface to improve its appearance or performance. It involves using abrasive materials such as polishing compounds or machinery like buffers to remove imperfections and create a smooth, glossy finish. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrolytic process used to increase the thickness of the natural oxide layer on the surface of metal parts. This not only enhances corrosion resistance but also provides a variety of decorative finishes. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form where colors are applied to a surface using various techniques. It serves as a creative outlet for artists to express emotions, thoughts, and ideas through imagery. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a chemical conversion coating used to give ferrous metals a black appearance while also providing corrosion resistance. This finish is commonly used in industries such as automotive, aerospace, and firearms. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process in which a thin layer of metal is deposited onto an object using electricity. This technique is commonly used to improve the appearance, corrosion resistance, or conductivity of various materials. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a method of applying a dry powder to a metal surface, which is then cured under heat to create a durable, protective finish. It is a popular alternative to traditional liquid paint for its environmental benefits and long-lasting results. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine is a chemical conversion coating used on aluminum and other metals to increase corrosion resistance and improve adhesion of paint. It creates a protective layer that can be clear or provide a base for paint or other coatings. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a chemical process that removes free iron and other surface contaminants from stainless steel. This creates a protective oxide layer that prevents corrosion, ensuring the material's longevity and performance. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a chemical process used to deposit a metal layer onto a surface without the need for electricity. It is a precise and efficient method commonly used in industries for coating various materials. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Indiana, USA

Our workforce includes surface treatment specialists with years of proven success.

FAQ

Here, some of the most common questions about CNC machining services for Indiana, USA. ” free to contact us if you have any question.”

FAQs for CNC Machining Services in Indiana, USA

Q: What is CNC machining?

A: CNC machining is a manufacturing process that uses computer-controlled machines to create precise and complex parts from various materials.

Q: What industries can benefit from CNC machining services?

A: Industries such as aerospace, automotive, medical, and electronics can benefit from CNC machining services for the production of high-quality parts.

Q: How can I find a reliable CNC machining service in Indiana?

A: Look for a company with a proven track record of delivering quality parts on time and within budget. Reading customer reviews and requesting quotes can also help in choosing the right service provider.

Q: What materials can be used in CNC machining?

A: CNC machining can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites.

Q: How long does it take to complete a CNC machining project?

A: The time taken to complete a CNC machining project depends on factors like complexity, material, and quantity. Generally, simple projects can be completed in a few days, while more complex projects may take weeks.

Q: Can CNC machining services help in prototyping?

A: Yes, CNC machining services are often used in prototyping to quickly create prototypes for testing and evaluation before full-scale production.

Q: What is the difference between CNC milling and CNC turning?

A: CNC milling involves cutting and drilling materials, while CNC turning involves rotating a workpiece against a cutting tool to create cylindrical shapes.

Q: Is CNC machining cost-effective for small batch production?

A: Yes, CNC machining can be cost-effective for small batch production as it eliminates the need for expensive tooling and reduces the setup time for each part.

Q: Can CNC machining services provide custom solutions?

A: Yes, CNC machining services can provide custom solutions tailored to the specific needs and requirements of each project.

Q: What are the benefits of using CNC machining services?

A: The benefits of using CNC machining services include increased precision, repeatability, efficiency, and overall quality of the finished parts.