CNC machining services forUSA

Get tailored, top-tier parts delivered fast

Our CNC machining services, in USA , makes high quality components for your requiements.

Welcome to DongGuan ChengYang, your premier destination for high-quality CNC machining services for Kansas. With years of experience and expertise in the industry, we pride ourselves on delivering top-notch precision machining solutions to meet all your needs.

Our state-of-the-art facility is equipped with cutting-edge technology and equipment, allowing us to provide a wide range of CNC machining services for industries in Kansas. Whether you require prototyping or production runs, our skilled team of engineers and technicians are dedicated to delivering exceptional results with quick turnaround times.

At DongGuan ChengYang, we understand the importance of precision and quality in every project we undertake. Trust us to be your reliable partner in CNC machining services for Kansas, and let us help bring your vision to life.

CNC Machining services

Dongguan Chengyang are equipped with 3-axis, 4-axis, and 5-axis CNC milling machines, helps us to skillfully handle parts ranging from easy to complicated.

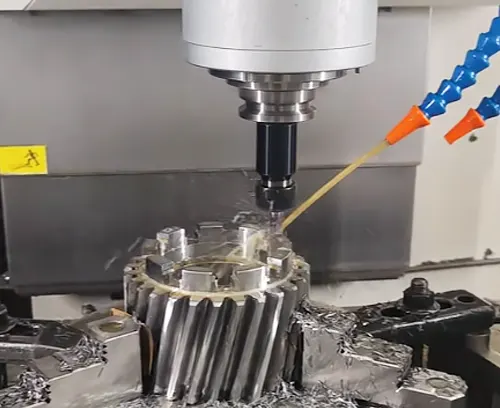

CNC Milling

Utilizing both CNC technologies for versatile production, producing high-performance parts efficiently for our clients.

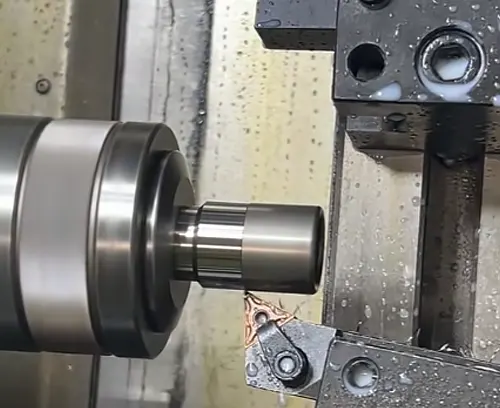

CNC Turnning

Our CNC lathes, turning centers, and mill-turn equipment enable us withhigh quality to fabricate a broad range of components for every consumer.

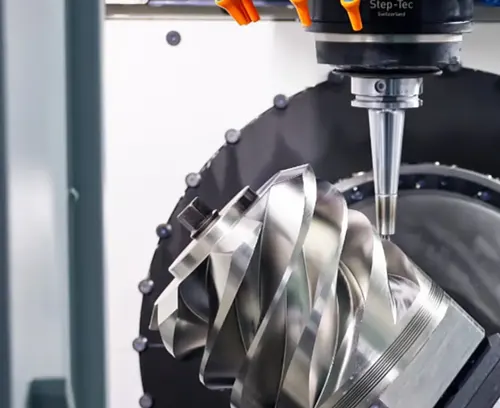

5 Axis CNC Milling

Equip with 5-axis machining solutions for complex and finely calibrated components. Featuring rapid machining, it's perfect for elaborate designs.

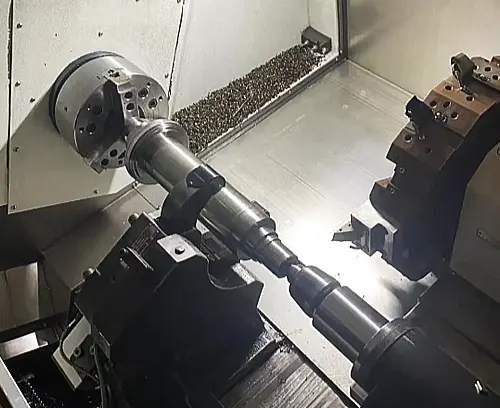

Precision Machining

Offer advanced manufacturing capabilities by streamlining diverse operations to enhance productivity, accuracy, and speed up delivery, guaranteeing reliable, high-quality output.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

Early design optimization through DFM ensures better production performance and lower costs.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

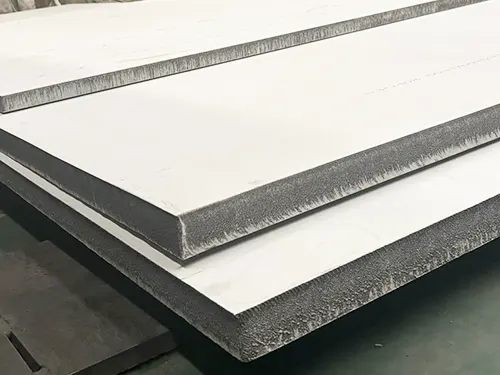

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.Get fast, reliable quotes for 100+ metals while exploring processing cost options.

Aluminum

Aluminum is a widely used material for CNC machining due to its lightweight, durable, and corrosion-resistant properties. It is also known for its excellent machinability, allowing for intricate and precise parts to be manufactured with ease. Some common types of aluminum materials used in CNC machining include 6061, 7075, and 2024. 6061 aluminum is versatile, offering good strength and weldability. 7075 aluminum is known for its high strength-to-weight ratio, making it ideal for aerospace and automotive applications. 2024 aluminum is valued for its high strength and fatigue resistance. Each type of aluminum material has its own unique characteristics, making them suitable for a wide range of industries and applications in CNC machining.

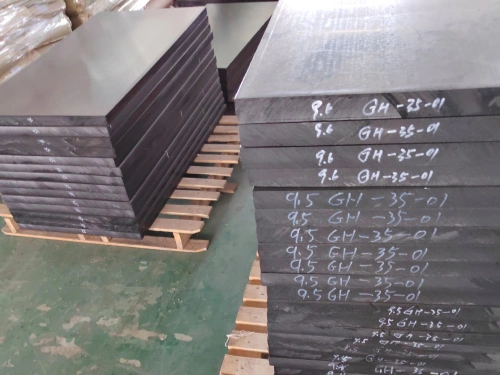

Carbon Steel

Carbon steel is a popular material used in CNC machining due to its versatility, durability, and affordability. It is composed of iron and carbon, with varying levels of other elements such as manganese, sulfur, phosphorus, and silicon. Some common types of carbon steel used in CNC machining include low carbon steel, medium carbon steel, and high carbon steel. Low carbon steel, also known as mild steel, is easily machinable and commonly used for parts that do not require high strength. Medium carbon steel is stronger and more wear-resistant, often used in gears and machinery parts. High carbon steel, with a higher carbon content, is extremely hard and tough, making it suitable for tools like drill bits and cutting blades.

Stainless Steel

Stainless steel is a popular material used in CNC machining due to its excellent corrosion resistance, high strength, and durability. It is a type of steel alloy that contains a minimum of 10.5% chromium, which creates a protective layer on its surface, preventing rust and corrosion. Common types of stainless steel used in CNC machining include 304 stainless steel, known for its versatility and excellent formability; 316 stainless steel, which offers superior corrosion resistance and strength; and 17-4 stainless steel, prized for its high strength and hardness. These different types of stainless steel allow for a wide range of applications in various industries, making them a popular choice for CNC machining processes.

Tool Steel

Tool steel is a type of carbon and alloy steel that is specifically designed for making tools used in the machining industry. It is known for its hardness, wear resistance, and ability to maintain a sharp cutting edge even at high temperatures. Some common types of tool steel used for CNC machining include H13, D2, A2, M2, and S7. H13 tool steel is known for its hot hardness and resistance to thermal fatigue, making it ideal for hot work applications. D2 tool steel is highly wear-resistant and is often used for cutting and punching tools. A2 tool steel is known for its high toughness and resistance to cracking, making it suitable for cold work applications. M2 tool steel is a high-speed steel that is commonly used for cutting tools. S7 tool steel is known for its shock resistance and high impact strength, making it ideal for impact and cold work applications.

Brass

Brass is a popular material used in CNC machining due to its excellent machinability, corrosion resistance, and attractive appearance. Brass is an alloy of copper and zinc, with varying compositions depending on the desired properties. Common types of brass materials used in CNC machining include C36000 (free-cutting brass), C46400 (naval brass), C26000 (cartridge brass), and C38500 (architectural bronze). C36000 is widely used for its excellent machining properties, while C46400 is preferred for applications requiring high strength and corrosion resistance. C26000, also known as yellow brass, is popular for its aesthetics and affordability. Lastly, C38500 is commonly used for architectural applications due to its warm golden color and resistance to atmospheric corrosion.

Copper

A cooper for CNC machining is a tool used to create precision cuts, holes, and shapes on various materials through computer-controlled movements. Common types of materials that can be machined using cooper include metals such as aluminum, steel, and brass, as well as plastics like acrylic and nylon. Each material requires specific cutting speeds, feed rates, and tool geometry to achieve the desired results. For example, aluminum is known for its high machinability and is often used in aerospace and automotive industries. Steel, on the other hand, is a durable but challenging material to machine due to its hardness. Understanding the characteristics of different materials is crucial in selecting the appropriate cooper and machining parameters for optimal performance.

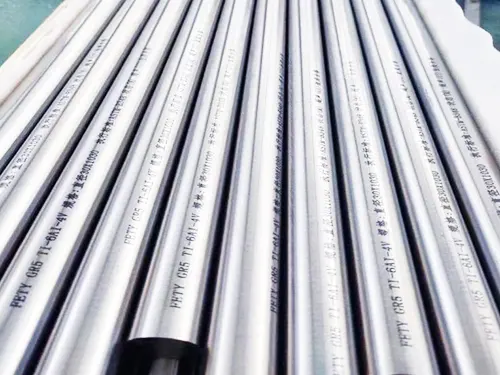

Titanium

Titanium is a popular material used in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and high temperature performance. These qualities make it ideal for aerospace, medical, and automotive industries. When used in CNC machining, titanium can be difficult to cut due to its toughness and tendency to work harden, which requires specialized tools and techniques. Some common types of materials that are often machined alongside titanium are aluminum, stainless steel, brass, copper, and plastics. Each material has its unique properties and requires specific cutting parameters to achieve optimal results in CNC machining.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic used in CNC machining. Its advantages include high strength, good impact resistance, and excellent chemical resistance. ABS also offers good dimensional stability and can be easily machined, making it a popular choice for a wide range of applications. However, ABS does have some disadvantages, such as limited heat resistance and poor UV stability, leading to potential issues with outdoor use. Additionally, ABS can be prone to warping during cooling, requiring proper machine settings and techniques to minimize this effect. Overall, ABS is a versatile material with many benefits for CNC machining, but it is important to consider its limitations when choosing it for a project.

PMMA

PMMA, or polymethyl methacrylate, is a popular material used in CNC machining due to its transparency, impact resistance, and ease of machinability. One advantage of PMMA is its optical clarity, making it ideal for applications requiring transparency, such as prototyping of optical components or medical devices. Additionally, PMMA is lightweight and can be easily machined into complex shapes, allowing for intricate designs to be realized. However, one disadvantage of PMMA is its relatively low heat resistance compared to other engineering plastics, making it vulnerable to melting or warping during high-speed machining processes. It is important to consider the thermal properties of PMMA when selecting it for CNC machining projects to ensure optimal results.

PE

PE for CNC machining stands for “Programmable Electronics”, which refers to the devices used to control the CNC machine during the machining process. The main advantage of using PE in CNC machining is the ability to precisely control and automate the movement of the machine, resulting in higher accuracy and efficiency in the manufacturing process. This also allows for complex and intricate designs to be easily produced with great precision. However, one disadvantage of using PE is the initial cost of acquiring and setting up the system, as well as the ongoing maintenance and training required to operate it effectively. Despite this drawback, the benefits of using PE for CNC machining far outweigh the drawbacks, making it an essential tool for modern manufacturing processes.

Nylon

Nylon is a versatile material used in CNC machining for its durability, resistance to abrasion, and low friction properties. Its advantages include high strength-to-weight ratio, excellent chemical resistance, and the ability to be easily machined to tight tolerances. Nylon also offers good wear resistance and can be used in various applications where high precision is required. However, Nylon does have some disadvantages such as poor resistance to UV radiation, limited heat resistance, and tendency to absorb moisture which can result in dimensional changes. Despite its limitations, Nylon remains a popular choice for CNC machining due to its overall performance and cost-effectiveness in producing high-quality parts.

PEEK

PEEK, or polyetheretherketone, is a high-performance thermoplastic material frequently used in CNC machining due to its excellent mechanical properties and resistance to high temperatures. Its advantages include exceptional strength and stiffness, as well as low thermal expansion. PEEK is also lightweight, chemically resistant, and has excellent dimensional stability. However, PEEK can be challenging to machine due to its toughness and high melting temperature, which can result in tool wear and longer processing times. Additionally, PEEK is more expensive than traditional materials, making it less cost-effective for certain applications. Despite its drawbacks, the unique combination of properties offered by PEEK makes it a popular choice for specialized CNC machining projects in industries such as aerospace, medical, and automotive.

PC

A PC for CNC machining refers to a personal computer that is used to operate computer numerical control (CNC) machines in manufacturing processes. The main advantage of using a PC for CNC machining is the ability to easily program and control the CNC machine for precise and accurate production. Furthermore, PC software for CNC machines allows for complex designs and shapes to be produced with high accuracy. However, a disadvantage of using a PC for CNC machining is the potential for system errors or crashes that could result in costly production delays. Additionally, PC software for CNC machines can be complex and require training for operators to fully utilize its capabilities. Overall, a PC for CNC machining offers advanced technological features for efficient production, but also comes with certain challenges that need to be managed.

PP

PP (Polypropylene) is a widely used material in CNC machining due to its low cost, excellent chemical resistance, and overall versatility. Its advantages include high strength-to-weight ratio, excellent impact resistance, and good fatigue resistance. PP is also easy to machine and has good dimensional stability. However, its low heat resistance can be a disadvantage when it comes to machining high-temperature parts. Additionally, PP can be prone to warping if not properly handled during the machining process. Overall, PP is a popular choice for CNC machining projects that require a cost-effective and durable material, but careful consideration must be taken to mitigate its limitations.

PET

PET, or polyethylene terephthalate, is a common plastic material used in CNC machining due to its excellent mechanical and thermal properties. One of the main advantages of using PET for CNC machining is its high strength-to-weight ratio, making it ideal for producing parts that require durability and stability. Additionally, PET is resistant to chemicals and moisture, making it suitable for various industrial applications. On the other hand, PET can be challenging to machine due to its tendency to warp under high temperatures, which can lead to dimensional inaccuracies in the finished product. Despite this drawback, with proper equipment and techniques, PET can be successfully machined to create high-quality precision parts for a wide range of industries.

POM

POM, or Production Order Management, is a crucial component in CNC machining that helps streamline the production process. By providing a detailed plan for the machining operations, POM ensures efficient utilization of resources and timely completion of orders. One of the key advantages of using POM in CNC machining is improved organization and coordination of production tasks, leading to increased productivity and reduced lead times. Additionally, POM allows for better monitoring and control of the production process, helping to identify and address any issues or bottlenecks in real-time. However, a potential disadvantage of POM is the initial investment required for implementing the system and training staff on its use. Nevertheless, the benefits of POM far outweigh the drawbacks, making it an essential tool for optimizing CNC machining operations.

PVC

PVC, or polyvinyl chloride, is a popular material used in CNC machining due to its versatility and cost-effectiveness. One of the main advantages of using PVC for CNC machining is its ease of machinability, making it ideal for complex shapes and intricate designs. Additionally, PVC is lightweight and has good corrosion resistance, making it suitable for a wide range of applications. However, there are some disadvantages to using PVC for CNC machining as well. PVC can produce harmful fumes when machined at high speeds, which can be hazardous to the health of operators. Additionally, PVC has poor heat resistance and can deform or melt at high temperatures, limiting its potential uses in certain applications.

Surface Finishes

Our surface treatment professionals ensure top-quality finishes through proven techniques.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is the act of using a toothbrush with toothpaste to clean the teeth and gums. It helps remove plaque, food debris, and bacteria to prevent cavities, gum disease, and bad breath. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting is a method used to clean, refinish, or shape surfaces through the use of abrasive materials propelled at high speeds. It is commonly used in industrial and construction settings for various applications. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves performing acrobatic movements such as flips, twists, and somersaults. It requires strength, flexibility, and body control to execute these movements safely and effectively. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a process used to smooth and enhance the surface of various materials, such as metal, wood, or glass. It involves using abrasive tools or chemicals to remove imperfections and create a shiny, smooth finish. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that enhances the corrosion resistance and aesthetic appeal of metal surfaces. It involves forming a more durable oxide layer on the material through controlled oxidation. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form that involves applying paint onto a surface to create an image or artwork. It can be done with various techniques and styles, using different tools like brushes, palette knives, or even fingers. Each painting conveys a message, tells a story, or captures a moment in time through colors, shapes, and textures. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a chemical conversion coating used to blacken ferrous metals. It provides a durable coating that helps prevent corrosion and increases the metal's wear resistance, making it a popular choice for industrial applications. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process in which a metal or other material is deposited onto a surface using an electrical current. This technique is often used to improve the appearance or properties of an object, such as adding corrosion resistance or enhancing conductivity. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process used to apply a decorative and protective finish to metal products. It involves applying a fine powder made of resin and pigment onto a surface that is then baked on, creating a durable and high-quality finish. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine is a chemical conversion coating used on aluminum and other metals to improve corrosion resistance and paint adhesion. It creates a protective barrier on the surface, enhancing the durability of the material. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a process used to make stainless steel surfaces more resistant to corrosion. This involves creating a protective layer on the metal, usually through exposure to an oxidizing agent such as nitric acid. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process where a metal coating is applied onto a surface without using an electrical current. This method utilizes chemical reactions to deposit a uniform and corrosion-resistant layer. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Kansas, USA

The professionals on our team are highly skilled in the art of product surface treatment.

FAQ

Here, some of the most common questions about CNC machining services for Kansas, USA. ” free to contact us if you have any question.”

FAQs about CNC Machining Services in Kansas, USA

Q: What is CNC machining?

A: CNC machining is a manufacturing process that uses computer-controlled tools to remove material from a workpiece to create a desired shape.

Q: How can CNC machining services benefit my business in Kansas?

A: CNC machining services can provide precise and efficient production of parts, reducing lead times and costs for your business.

Q: What materials can be used with CNC machining services in Kansas?

A: CNC machining services can work with a variety of materials, including metals, plastics, and composites.

Q: How do I choose the right CNC machining service provider in Kansas?

A: When selecting a CNC machining service provider, consider factors such as experience, capabilities, and customer reviews.

Q: How long does it take to complete a CNC machining project in Kansas?

A: The timeframe for completing a CNC machining project in Kansas can vary depending on the complexity of the part and the provider’s workload.

Q: What quality control measures are in place for CNC machining services in Kansas?

A: Quality control measures for CNC machining services in Kansas may include inspections, certifications, and compliance with industry standards.

Q: Can CNC machining services in Kansas accommodate custom designs?

A: Yes, CNC machining services in Kansas can work with custom designs to meet your specific requirements.

Q: What is the difference between CNC milling and CNC turning services in Kansas?

A: CNC milling involves rotating cutting tools to remove material, while CNC turning rotates the workpiece against stationary cutting tools.

Q: Are CNC machining services in Kansas cost-effective for small businesses?

A: Yes, CNC machining services in Kansas can be cost-effective for small businesses due to their efficiency and precision.

Q: How can I request a quote for CNC machining services in Kansas?

A: To request a quote for CNC machining services in Kansas, reach out to a service provider with your project specifications for pricing details.