CNC machining services forUSA

Get finely crafted parts at your convenience

Our CNC machining services, in USA , makes precision components for your needs.

Welcome to DongGuan ChengYang, your premier provider of CNC machining services for Missouri. With years of experience and a dedication to precision, we are dedicated to offering top-notch machining solutions for clients in Missouri and beyond.

Our team at DongGuan ChengYang is committed to exceeding your expectations with our CNC machining services for Missouri. From prototyping to production runs, we have the expertise and capabilities to handle a wide range of projects with unmatched precision and efficiency. Whether you are in the automotive, aerospace, or medical industry, we have the tools and knowledge to bring your designs to life.

When you choose DongGuan ChengYang for your CNC machining needs in Missouri, you can trust that you are working with a team that is dedicated to excellence. Contact us today to learn more about how we can help you achieve your machining goals with our top-of-the-line services tailored to meet the unique needs of clients in Missouri.

CNC Machining services

Dongguan C.Y. utilizes a full suite of CNC milling equipment—including 3-axis, 4-axis, and 5-axis CNC milling machines, provides us to productively machining parts ranging from plain to elaborate .

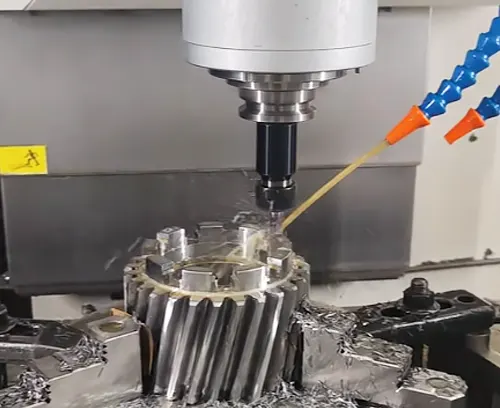

CNC Milling

Equipped with CNC mills for precision machining, ensuring top-quality components are delivered with speed and accuracy.

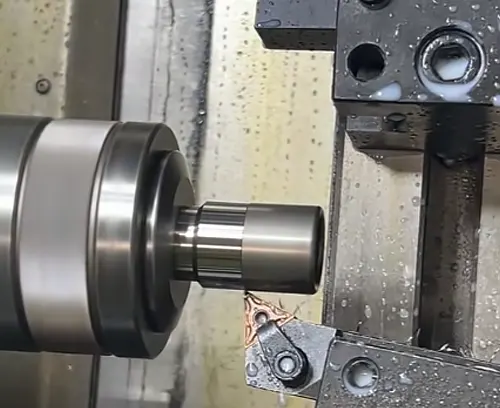

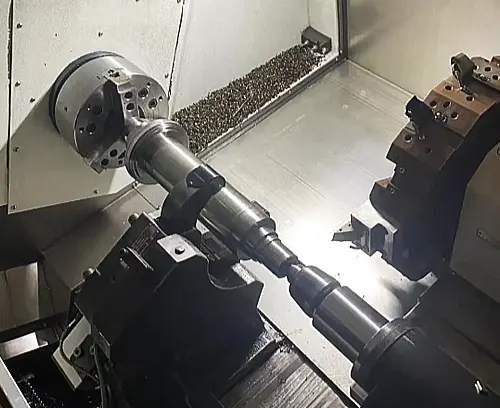

CNC Turnning

Our CNC lathes, turning centers, and mill-turn equipment enable us withefficiency to construct a broad range of parts for every buyer.

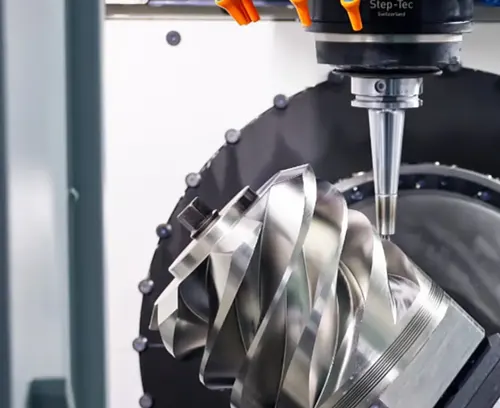

5 Axis CNC Milling

Equip with 5-axis machining solutions for complex and finely calibrated components. Featuring speed production, it's perfect for intricate designs.

Precision Machining

Deliver high-precision machining by combining several production phases to maximize efficiency, precision, and minimize delays, maintaining high standards in every batch.

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Material Available

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium, and plastic, etc .

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Common CNC DFM

Design for Manufacturing (DFM) simplifies production by refining a product‘s design early, helping reduce costs and avoid manufacturing errors.

Sharp Corner

Undercut

Undercut

Thick Walls

Tolerance Guide

Small Hole

Narrow Area

Metal Materials

We offer instant quotes for over 100 metals and help compare processing material costs.Get fast, reliable quotes for 100+ metals while exploring processing cost options.

Aluminum

Aluminum is a popular material used in CNC machining due to its excellent machinability, corrosion resistance, and lightweight properties. It is commonly chosen for a wide range of applications, including automotive parts, aerospace components, and consumer electronics. Some common types of aluminum materials used in CNC machining include 6061-T6, known for its good strength and weldability, 7075-T6, which offers high strength and hardness, 2024-T3, a high-strength aluminum alloy with good machinability, and 5052-H32, preferred for its formability and corrosion resistance. Each type of aluminum material offers unique properties that make it suitable for specific types of CNC machining projects, allowing for versatility and precision in manufacturing processes.

Carbon Steel

Carbon steel is a widely used material in CNC machining due to its durability, strength, and affordability. It is an alloy of iron and carbon, with carbon content varying from 0.05% to 1.5%. Common types of carbon steel used in CNC machining include low carbon steel (mild steel), medium carbon steel, and high carbon steel. Low carbon steel is easy to machine and weld, making it suitable for a wide range of applications. Medium carbon steel has increased strength and hardness, making it ideal for parts that require higher durability. High carbon steel is heat-treated for increased hardness and wear resistance, making it suitable for cutting tools and machine parts subjected to abrasion.

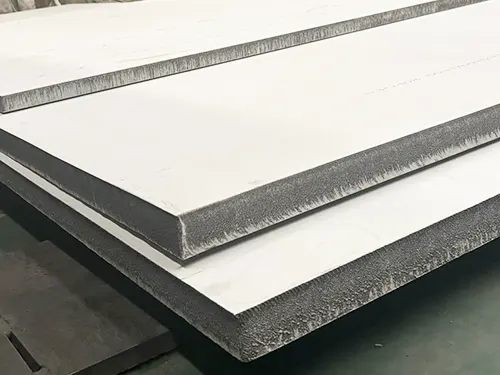

Stainless Steel

Stainless steel is a versatile and durable material commonly used in CNC machining due to its excellent properties, including corrosion resistance, high strength, and temperature resistance. This makes it suitable for a wide range of applications across various industries. Some common types of stainless steel materials used in CNC machining are 303 stainless steel, known for its excellent machinability and great for parts that require extensive machining; 304 stainless steel, a versatile material with good corrosion resistance and suitable for a wide range of applications; and 316 stainless steel, which offers superior corrosion resistance, making it ideal for parts used in harsh environments such as marine or chemical industries. Each type of stainless steel has its own unique composition and characteristics that make it suitable for specific applications in CNC machining.

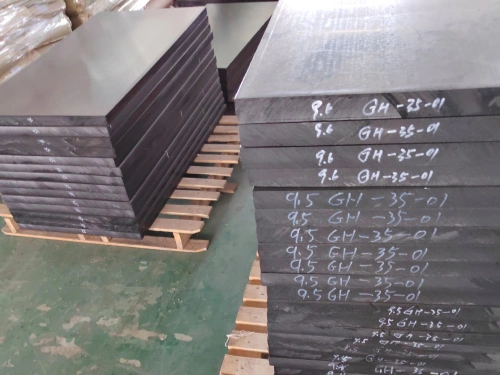

Tool Steel

Tool steel is a type of material that is specifically designed for use in CNC machining due to its high strength, toughness, and resistance to wear and tear. Common types of tool steel used in CNC machining include A2, D2, O1, and S7. A2 tool steel is known for its excellent wear resistance and toughness, making it ideal for cutting tools. D2 tool steel is highly wear-resistant and offers good stability during heat treatment. O1 tool steel is known for its excellent machinability and toughness. S7 tool steel is preferred for its high impact resistance and ability to retain hardness at elevated temperatures. Overall, tool steel is a crucial component in CNC machining operations for its ability to withstand the rigors of high-speed cutting and shaping processes.

Brass

Brass is a commonly used material in CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appeal. It is a metal alloy composed primarily of copper and zinc, with a wide range of compositions that can be tailored to suit specific machining requirements. Some common types of brass materials used in CNC machining include C26000 (cartridge brass), C36000 (free-cutting brass), and C46400 (naval brass). Each type of brass offers unique properties that make them suitable for various applications, such as precision components, hardware, and decorative pieces. Overall, brass is a versatile material that provides exceptional performance and can be effectively machined with high precision in CNC processes.

Copper

A cooper for CNC machining is a cutting tool used to shape or carve out materials on a computer numerical control (CNC) machine. It is essential for creating precise and accurate cuts on a variety of materials. Some common types of materials that can be machined with a cooper include aluminum, steel, brass, copper, plastics, and wood. Each material requires specific settings and parameters to achieve the desired results. Coopers come in different shapes and sizes, allowing for versatility in machining various parts and components. With the advancement of technology, coopers have become more durable and efficient, resulting in faster production times and higher quality finished products.

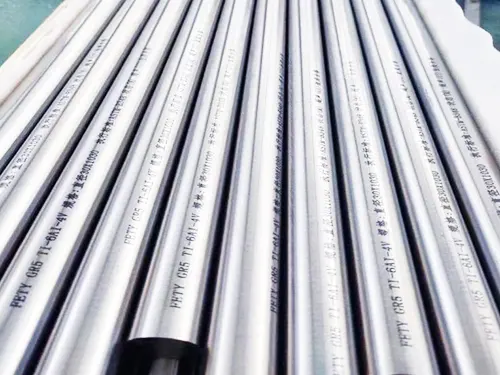

Titanium

Titanium is a popular material used in CNC machining due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. It is commonly used in industries such as aerospace, medical, and automotive for producing high-performance components and parts. Some common types of titanium materials used in CNC machining include Grade 5 titanium (Ti-6Al-4V), Grade 2 titanium (commercially pure titanium), and Grade 23 titanium (Ti-6Al-4V ELI). These different grades offer varying levels of strength, hardness, and machinability, making them suitable for a wide range of applications. When selecting a titanium material for CNC machining, it is important to consider the specific requirements of the project in order to choose the most appropriate grade.

Plastic Materials

We offer instant quotes for over 200 plastics and help compare processing material costs.

ABS

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic material used in CNC machining due to its excellent mechanical properties. One of the main advantages of using ABS for CNC machining is its high impact resistance, making it suitable for producing durable parts and prototypes. Additionally, ABS is known for its good machinability, allowing for easy fabrication and finishing of complex shapes. However, one of the disadvantages of ABS is its tendency to warp during the cooling process, leading to dimensional inaccuracies in the final product. Furthermore, ABS is prone to chemical degradation and may not be suitable for applications that require high heat resistance. Overall, ABS is a versatile material for CNC machining with both advantages and disadvantages to consider when choosing it for a project.

PMMA

PMMA, or polymethyl methacrylate, is a transparent thermoplastic commonly used in CNC machining for its durability and optical clarity. Its advantages include high strength-to-weight ratio, resistance to UV radiation and weathering, and ease of machining. PMMA can be easily shaped and polished to achieve a variety of finishes, making it a popular choice for prototyping and small-scale production of optical components, signage, and medical devices. However, PMMA is prone to scratching and can be brittle, which can be a disadvantage in certain applications where impact resistance is critical. Additionally, PMMA has a lower heat resistance compared to other plastics, limiting its use in high-temperature environments. Overall, PMMA’s versatility and optical properties make it a valuable material for CNC machining, despite its limitations.

PE

PE, or Programming Environment, for CNC machining refers to the software used to create the instructions that control the cutting tools of a CNC machine. The advantage of using a PE for CNC machining is the ability to precisely program complex shapes and designs with high accuracy and efficiency. This software allows for automation of the machining process, increasing productivity and reducing errors. However, the disadvantage of using a PE for CNC machining is the initial learning curve required to master the software. It can be complex and time-consuming to understand all the functions and features of the programming environment. Nevertheless, the benefits of using a PE for CNC machining far outweigh the challenges, making it an essential tool for modern manufacturing processes.

Nylon

Nylon is a popular material used in CNC machining due to its excellent mechanical properties and versatility. It is known for its high chemical resistance, flexibility, and impact strength, making it ideal for a wide range of applications in various industries. One of the main advantages of using nylon for CNC machining is its ability to produce intricate, complex shapes with high precision. Additionally, nylon is lightweight and has good machinability, allowing for faster production times and reduced costs. However, nylon does have some disadvantages, such as its tendency to absorb moisture, which can affect its dimensional stability and mechanical properties. It also has a lower chemical resistance compared to other materials, which may limit its use in certain applications. Overall, nylon remains a popular choice for CNC machining due to its favorable properties and relatively low cost.

PEEK

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic material frequently used in CNC machining due to its excellent mechanical properties and chemical resistance. Its advantages include high temperature resistance, excellent wear and abrasion resistance, and low coefficient of friction, making it ideal for applications in demanding industries such as aerospace, medical, and automotive. PEEK also has good dimensional stability and can be easily machined to produce complex and precise parts. However, one major disadvantage of PEEK is its high cost compared to other engineering plastics, which can make it less cost-effective for some projects. Additionally, PEEK has poor UV resistance, limiting its outdoor applications.

PC

A PC for CNC machining, also known as a computer numerical control machine, serves as the control center for automated machining operations. Its primary advantage lies in its ability to precisely control the movements of cutting and shaping tools, increasing efficiency and accuracy in production. By inputting the necessary codes and parameters, operators can program intricate designs with minimal human error. Additionally, PCs for CNC machining can store and recall past programs, allowing for easy reproduction of parts or adjustments to existing designs. However, a disadvantage of relying on a PC for CNC machining is the potential for system malfunctions or crashes, leading to downtime and production delays. It is important for operators to have backup plans in place to mitigate these risks and ensure smooth operations.

PP

PP, or Polypropylene, is a common material used in CNC machining due to its low cost, excellent chemical resistance, and good overall mechanical properties. Its advantages include high strength-to-weight ratio, resistance to corrosion, and thermal stability. PP is also easy to machine and offers good dimensional stability. However, one disadvantage of PP is its relatively low melting point, which limits its use in high-temperature applications. Additionally, PP can be susceptible to warping and shrinkage during the machining process. Despite these drawbacks, PP remains a popular choice for CNC machining in a variety of industries due to its versatility and cost-effectiveness.

PET

PET, which stands for Polyethylene Terephthalate, is a common material used in CNC machining. One of the key advantages of PET is its excellent machinability, making it a popular choice for producing accurate and precise parts. Additionally, PET is known for its high strength and durability, allowing for long-lasting and reliable components. However, PET does have some drawbacks. One disadvantage is its tendency to warp when exposed to high temperatures, which can affect the final dimension of the part. Additionally, PET may not be suitable for applications that require resistance to chemicals or harsh environments. Despite these limitations, PET remains a versatile material for CNC machining, offering a good balance of cost-effectiveness and performance.

POM

POM, which stands for Polyoxymethylene, is a type of thermoplastic used in CNC machining. Its primary advantage is its excellent mechanical properties, including high strength, stiffness, and dimensional stability. POM also offers good resistance to abrasion, chemicals, and moisture. However, there are some disadvantages to using POM in CNC machining. One drawback is its relatively high cost compared to other plastic materials. POM also has a tendency to shrink during the cooling process, which can lead to dimensional inaccuracies in the final product. Despite these drawbacks, POM remains a popular choice for CNC machining applications that require precision, durability, and resistance to harsh environments.

PVC

PVC, or polyvinyl chloride, is a widely used material in the world of CNC machining. It is a thermoplastic polymer that is known for its versatility and cost-effectiveness. One of the main advantages of using PVC for CNC machining is its ease of machinability. It can be easily cut, drilled, and shaped to create intricate designs and complex parts. Additionally, PVC is resistant to corrosion, making it ideal for outdoor applications. However, there are some disadvantages to using PVC in CNC machining. One major drawback is that PVC is not as strong or durable as other materials like aluminum or steel, making it less suitable for high-stress applications. Additionally, PVC can release harmful fumes when heated, so proper ventilation is a must when working with this material.

Surface Finishes

Our experts are trained to deliver optimal results in product surface treatment.

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is a crucial part of maintaining good oral hygiene. It involves using a toothbrush and toothpaste to clean the teeth and gums, removing food particles and plaque to prevent cavities and gum disease. It should be done at least twice a day for optimal dental health. |

Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblast is a powerful method used for cleaning surfaces or shaping materials using high-velocity sand particles. This process is commonly used in industries like construction, automotive, and manufacturing for efficient surface preparation. |

All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a form of gymnastics that involves a series of acrobatic movements performed in succession. It requires strength, flexibility, and coordination. Tumblers perform flips, twists, and other impressive feats. |

All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is the process of smoothing a surface to improve its appearance or texture. It involves using abrasives to remove imperfections, scratches, or rough spots, resulting in a glossy, reflective finish. |

All Materials | N/A | Smooth | |

| Anodizing | Anodizing is an electrochemical process that enhances the surface of metals such as aluminum by creating a durable, corrosion-resistant finish. This process involves depositing a protective oxide layer on the metal, which not only increases its longevity but also allows for color customization. |

Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Painting is a visual art form where artists use various mediums to create images on a surface. It is a way to express ideas, emotions, and stories through colors, shapes, and textures. |

All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is a conversion coating used to create a corrosion-resistant black finish on various metals. It is commonly used for tools, firearms, and automotive parts to improve appearance and provide some level of protection. |

Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating is a process where a metal coating is deposited onto a conductive surface through the use of an electric current. This technique is commonly used to enhance the appearance, durability, and corrosion resistance of objects. |

Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a dry finishing process where finely ground particles of pigment and resin are sprayed onto a surface. This creates a uniform, durable, and high-quality finish that is resistant to scratches, rust, and chemicals. |

Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | Alodine is a chemical conversion coating applied to aluminum and other metals to increase corrosion resistance, paint adhesion, and improve overall durability. It is commonly used in aerospace and military applications. |

Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation is a process used to make a material less susceptible to corrosion. It involves creating a protective layer on the surface that prevents the material from reacting with its environment. |

Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a process used to deposit a metallic coating onto a surface without the use of an external power source. It involves a chemical reaction between the metal ions and a reducing agent to create a uniform and corrosion-resistant finish. |

Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Gallery Parts

CNC machining services Locations Near Missouri, USA

We apply advanced surface treatment techniques through a team of seasoned professionals.

FAQ

Here, some of the most common questions about CNC machining services for Missouri, USA. ” free to contact us if you have any question.”

FAQs About CNC Machining Services for Missouri, USA

Q: What industries can benefit from CNC machining services in Missouri?

A: CNC machining services in Missouri are beneficial for a wide range of industries, including aerospace, automotive, medical, and electronics.

Q: How precise are CNC machined parts?

A: CNC machined parts are extremely precise, with tolerances as tight as +/- 0.005 inches, ensuring high quality and accuracy.

Q: What materials can be used in CNC machining services?

A: CNC machining services in Missouri can work with a variety of materials, including aluminum, steel, titanium, and plastics.

Q: How long does it take to complete a CNC machining project?

A: The time to complete a CNC machining project in Missouri will vary depending on the complexity and size of the part, but turnaround times are typically quick.

Q: What CAD software is used in CNC machining services?

A: CNC machining services use industry-standard CAD software like SolidWorks and AutoCAD to design and program parts for machining.

Q: Can prototypes be created through CNC machining services?

A: Yes, CNC machining services in Missouri can quickly and cost-effectively produce prototypes for testing and validation.

Q: What is the maximum size of parts that can be machined?

A: CNC machining services in Missouri can handle parts up to 40 inches in length and width, making them suitable for a wide range of applications.

Q: Are CNC machined parts durable and long-lasting?

A: Yes, CNC machined parts are known for their durability and longevity, making them ideal for use in demanding applications.

Q: How affordable are CNC machining services in Missouri?

A: Despite their precision and quality, CNC machining services in Missouri are cost-effective and offer excellent value for money.

Q: Can custom designs be accommodated in CNC machining services?

A: Yes, CNC machining services in Missouri can accommodate custom designs and unique specifications to meet the needs of each client.

In conclusion, CNC machining services in Missouri offer a wide range of benefits for various industries, providing precision, quality, and cost-effectiveness. With the ability to work with a variety of materials and produce prototypes quickly, CNC machining services are essential for companies looking to create high-quality parts and components. If you have additional questions about CNC machining services, feel free to reach out to a reputable machining company for more information.